Nabors HMI Full Platform Redesign

Nabors Industries is a global provider of drilling and rig services for the oil and gas industry, renowned for its advanced technology and innovative approaches. Operating one of the world’s largest land-based drilling rig fleets, they offer a wide range of services, including land and offshore drilling. The BORN team, having developed the new operating system for rigs in the field, was brought on to further develop the human-machine interface for Nabors’ new rig, specifically designed for automation.

Role

Senior Designer

Supporting Practices

Product Management, Robotics and Engineering

Agency

BORN Group

I led the overall product design and user research efforts to ensure the platform exceeded the standards and practices needed for drillers to accomplish their tasks. Additionally, I utilized and evolved a robust component library to accelerate the workflow.

OVERVIEW

Create a human machine interface for drillers to use and monitor tasks in automation as well as take manual control of equipment

Build upon new interface designs to match operating system

Usability test new interface’s efficacy with drillers

Goals & Objectives

PROJECT KPIs

Effectively cut down duplicative or redundant screens across the platform by 90%

Decreased the number of screens that drillers had to view at a time from 3 to 2 screens, reducing overall cognitive load when carrying out day-to-day tasks.

Successfully crafted a strong experience for automation, working in tandem with robotics.

Created a new experience with a 50% adoption rate from drillers.

CONTEXTUAL INQUIRY AND USER RESEARCH

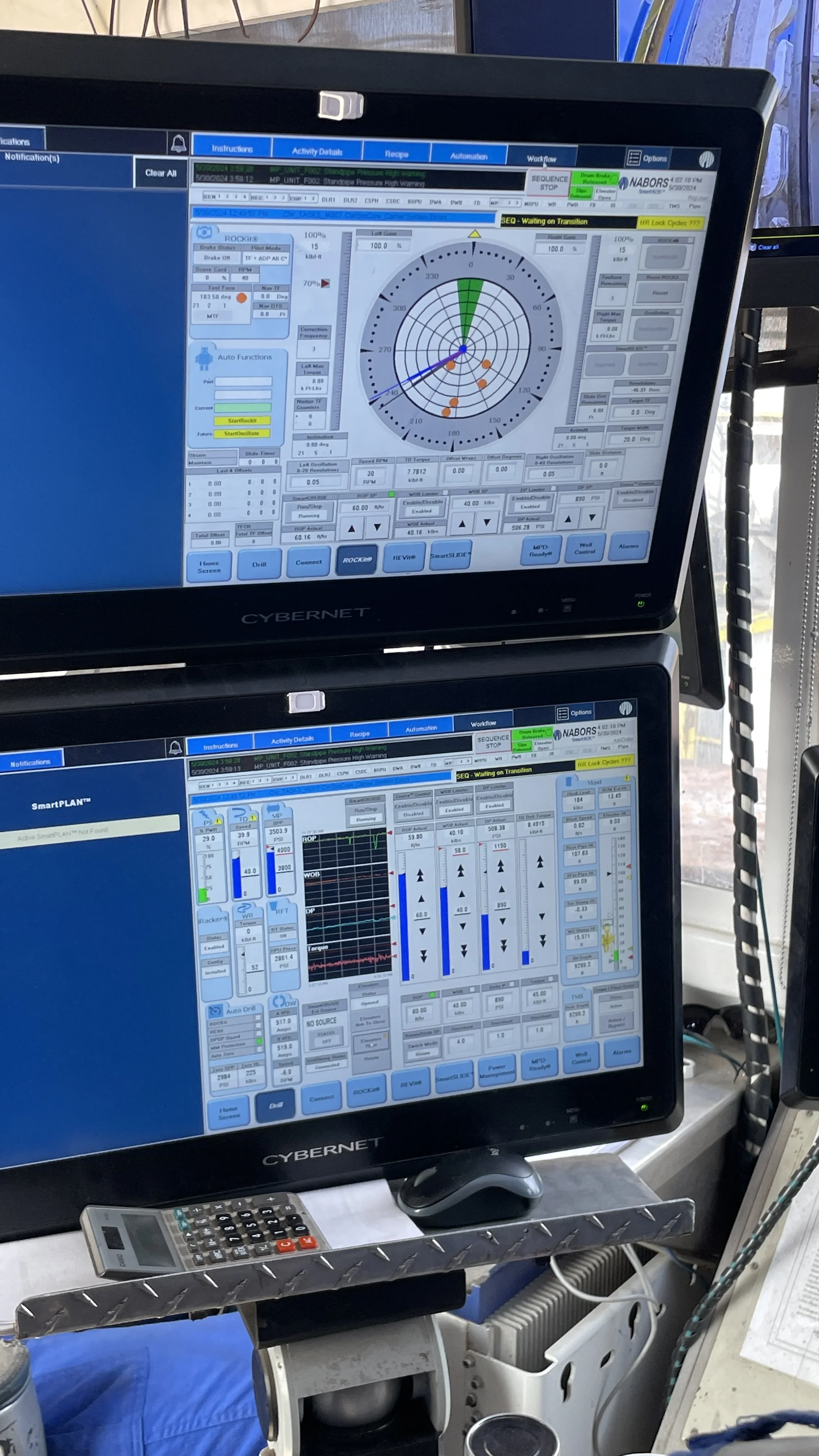

Myself and the team traveled to Midland, TX to go on-site with the Nabors team and their drillers where we could observe how driller’s accomplish their day-to-day tasks in a 24 hour cycle and the systems they currently used.

During the contextual inquiry we were able to see how equipment was changed out of automation to then be brought into manual control. We were also able to see how driller’s interacted with the touch screen interface. Scrolling vertically was an established pattern as well as quickly touching elements on the screen to have modals appear.

We were able to view different processes like tripping in (drilling the initial hole) and drilling.

INSIGHTS & RECOMENDATIONS

After returning from Midland, TX we compiled a list of insights and recommendations that were observed to better align stakeholders on scope while also giving us a strong foundation to follow once we started designing the RZR platform.

Onsite Driller

In charge of day-to-day drilling activities. Driller reports to Rig Manager and coordinated with others for the rig.

Environmental Considerations:

Doghouse

Works day shift and night shifts

All weather

Lots of equipment, noise and distractions

Uses cameras, screens, UI to see what’s going on around them

Age and hearing ability

Remote Performance Driller

View only, does air traffic control, oversee multiple drillers/certain activities. Focused on optimization.

Environmental Considerations:

General office building

1 person looking at 24 screens and 40 rigs, but only 20-30 working at a time

Ideal screen setup would be 12 screens and 20-30 jobs; operate with a dashboard

15 users total

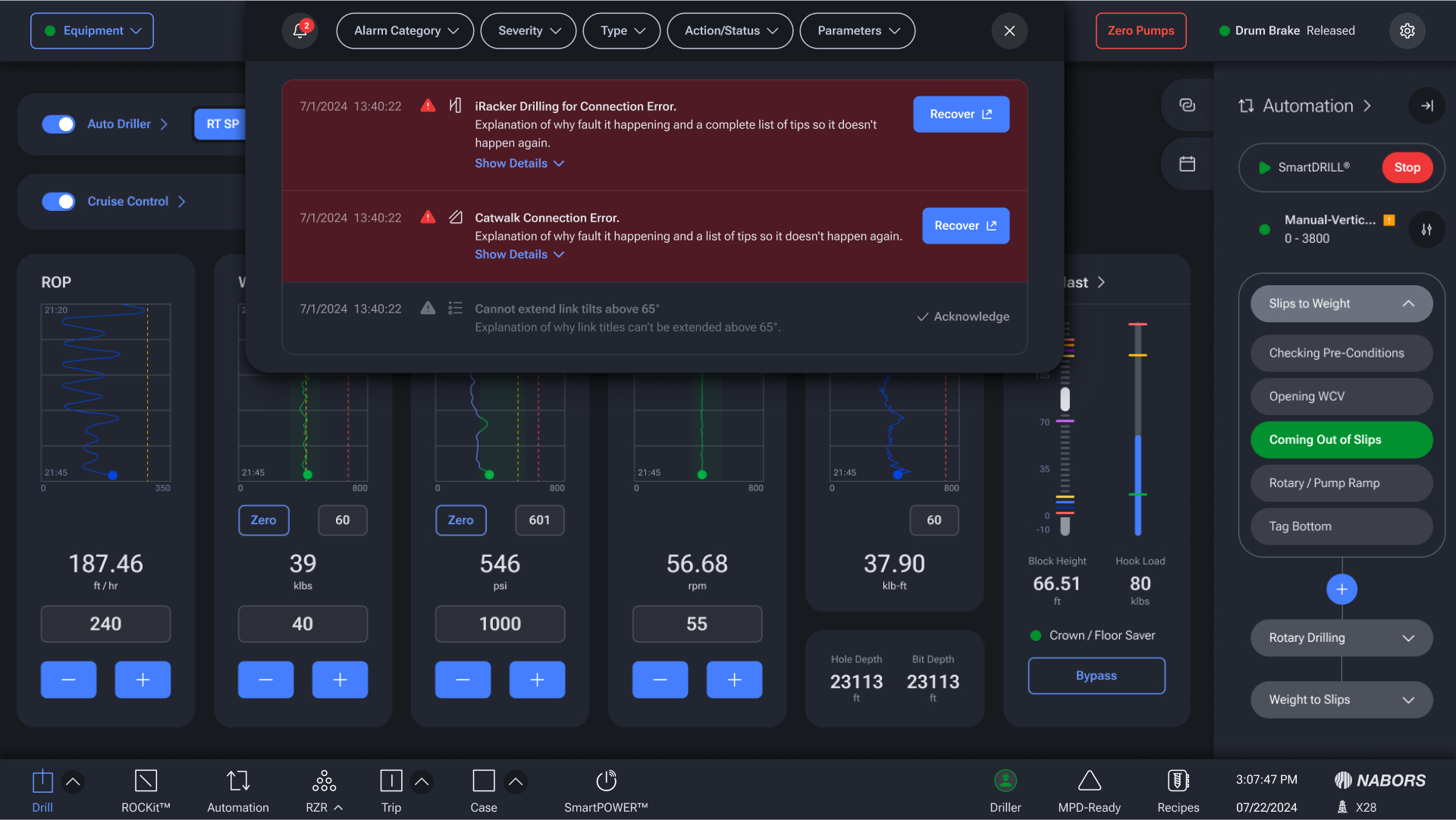

With the introduction of RZR, Drillers have even more responsibilities than they do on traditional rigs since they are responsible for monitoring and recovering from tasks that are usually accomplished by floor hands. With an increased workload - and the addition of one more HMI screen - Drillers have the potential to get overwhelmed.

Divided Attention

Recommendation

Eliminate the need for looking at 3 different HMIs by consolidating related tasks and screens together

Broadcast alerts across different screens to inform Drillers of critical conditions that require their attention

Continue to use sound and vary tones based on the type of alert

RZR relies on automation to ensure worker safety, but the more automation, the less the Driller potentially has to do as the machinery gets more efficient and accurate. As tasks move from action to monitoring, keeping Drillers alert on long shifts is an important goal. During our visit, we didn’t notice a drop in RZR Driller activity from traditional rigs, especially since their workload has increased, but over time, ensuring that the driller is engaged “in the loop” is always an important consideration.

Retaining Drillers Attention During Shift

Maintain task flows that require confirmation of key activities

Look for potential activities that Drillers can add their skill in identifying faults before they happen and proactively assist the machinery

Recommendation

RZR adds more equipment and screens to the SmartROS platform making the Driller’s operational path longer and more difficult for certain tasks within the HMI. In order to find the specific action they are looking for, Drillers need to parse through more information and then traverse various screens to complete tasks such as recovering from the iRacker missing a pipe grab.

Inefficient Interactions / Workflows

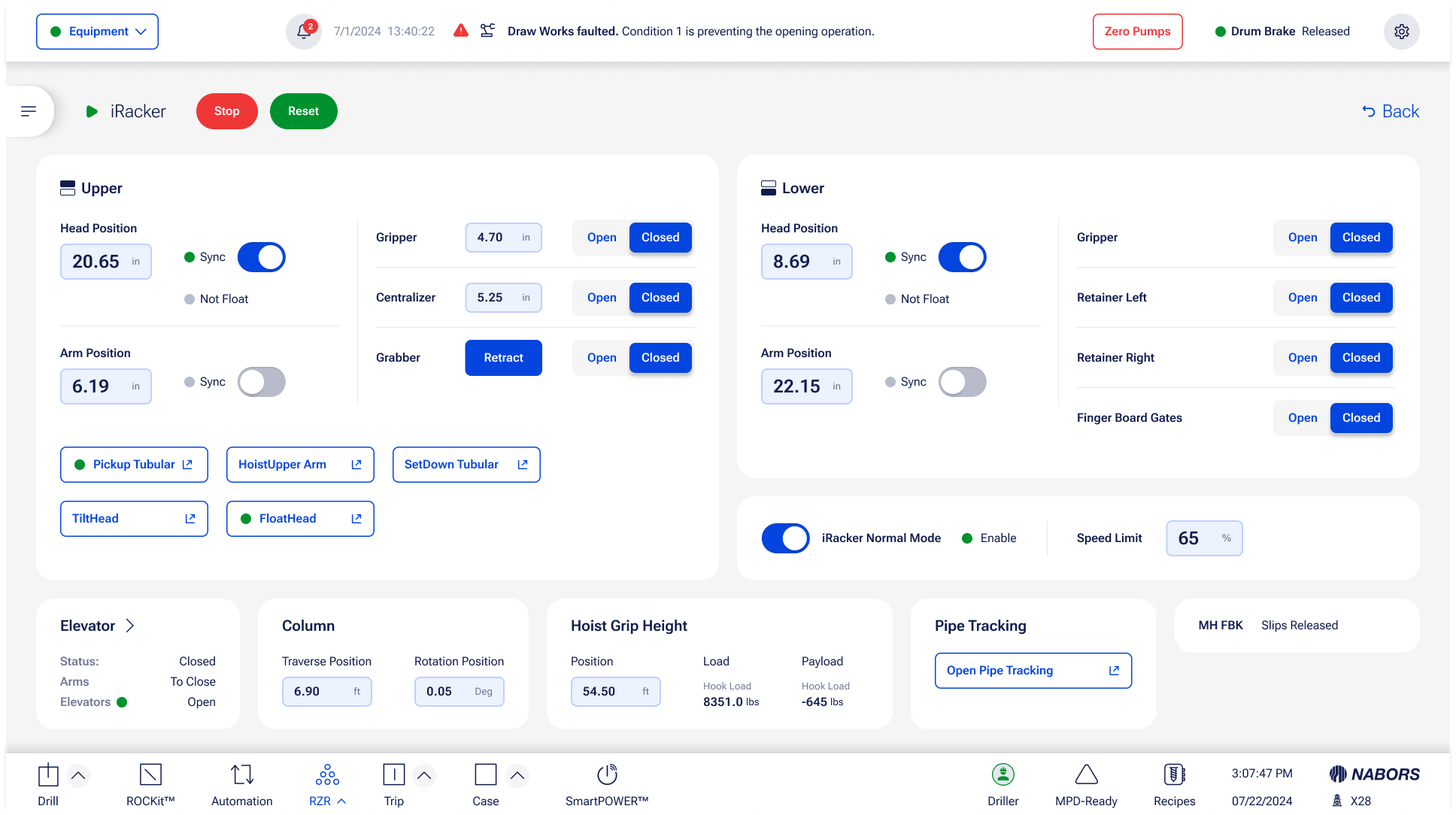

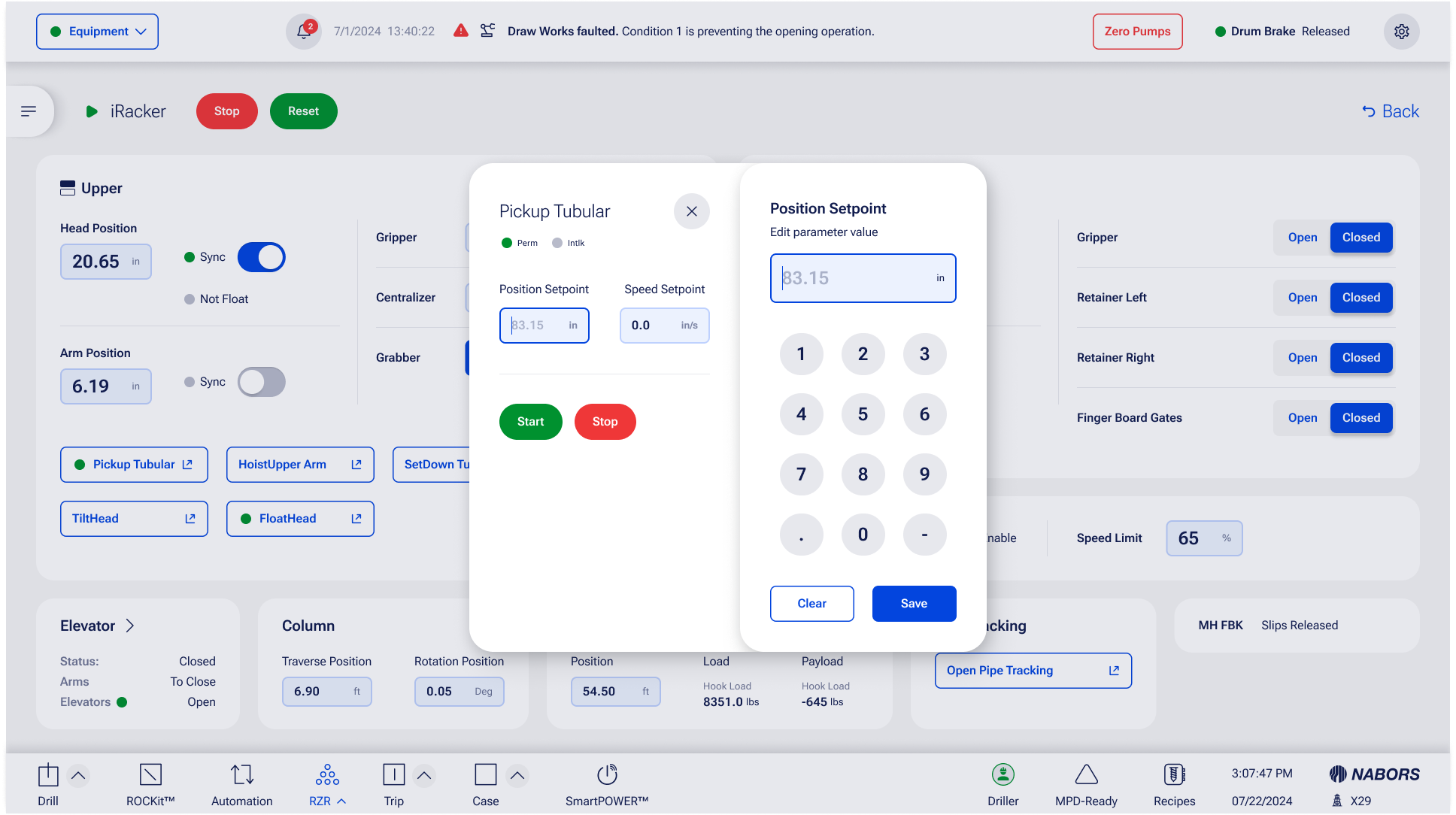

Consolidate related info and tasks together such as upper and lower arms in the iRacker into a single screen without having to navigate different pages

Recommendation

RZR screens don’t take advantage of available screen space and either have very little on screen or don’t efficiently organize or prioritize an abundance of controls. The screens don’t capitalize on the patterns set in the new SmartROS platform.

Inefficient Layouts

Use the full width of the screen to enable more components to fit on a single screen as long as they are grouped and spaced out appropriately

Re-organize controls on and across pages according to function and priority using available space

Use new SmartROS patterns to facilitate the process of laying out controls in a more efficient, condensed, and organized way

Recommendation

Several screens, states and sections were identified that needed to be heavily redesigned or created for RZR’s new automation platform:

Dedicated RZR Screen (Net New)

Tubular Management System Redesign (TMS)

Zone Management System Redesign (ZMS)

Notifications and Alerts

Catwalk (Integrated and Standalone)

Wrench (Integrated and Standalone)

iRacker

Trip Screen Redesign

Specific equipment screens like Catwalk and Wrench also needed to be developed both for RZR and as individual SaaS solutions.

EVOLVING THE CURRENT PLATFORM

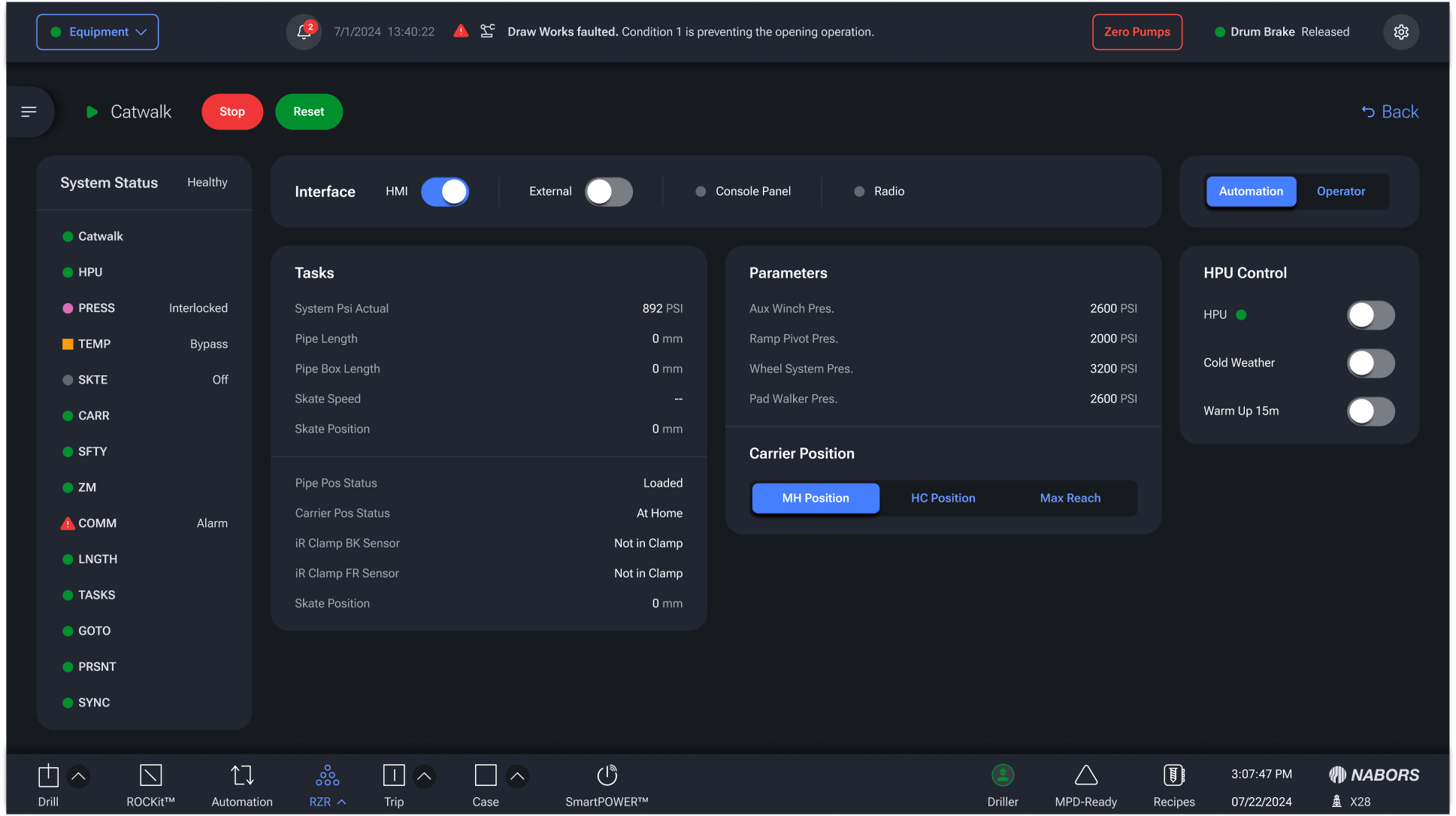

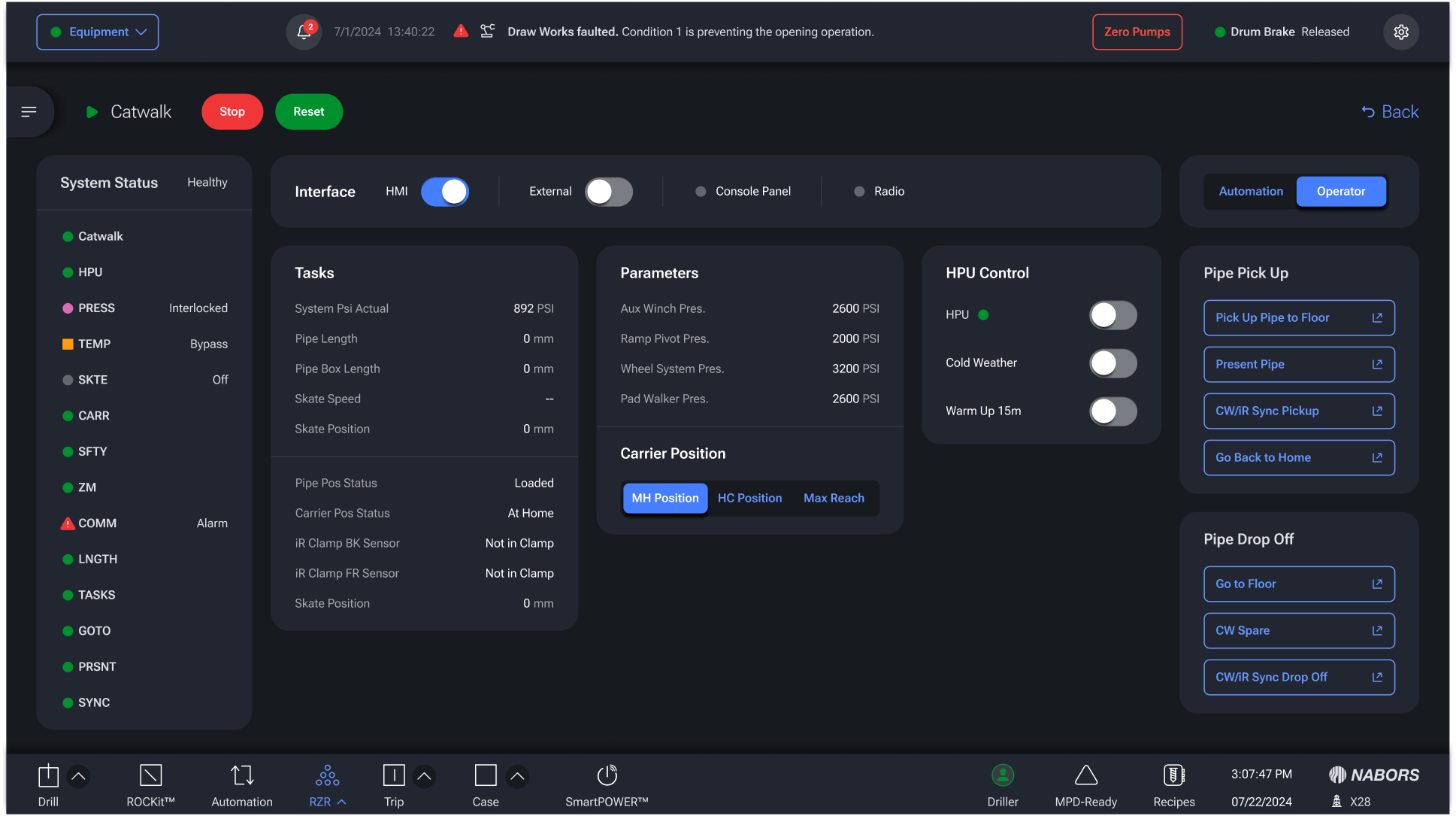

As we moved into version 1 of the RZR design platform, our primary goals based on what we saw from our on-site research was to reduce the number of duplicative or redundant elements on equipment screens and leverage the already existing component library that the BORN team had develop two years prior. We also ensured that both light and dark mode themes worked properly and would be able to comply with any and all accessibility needs.

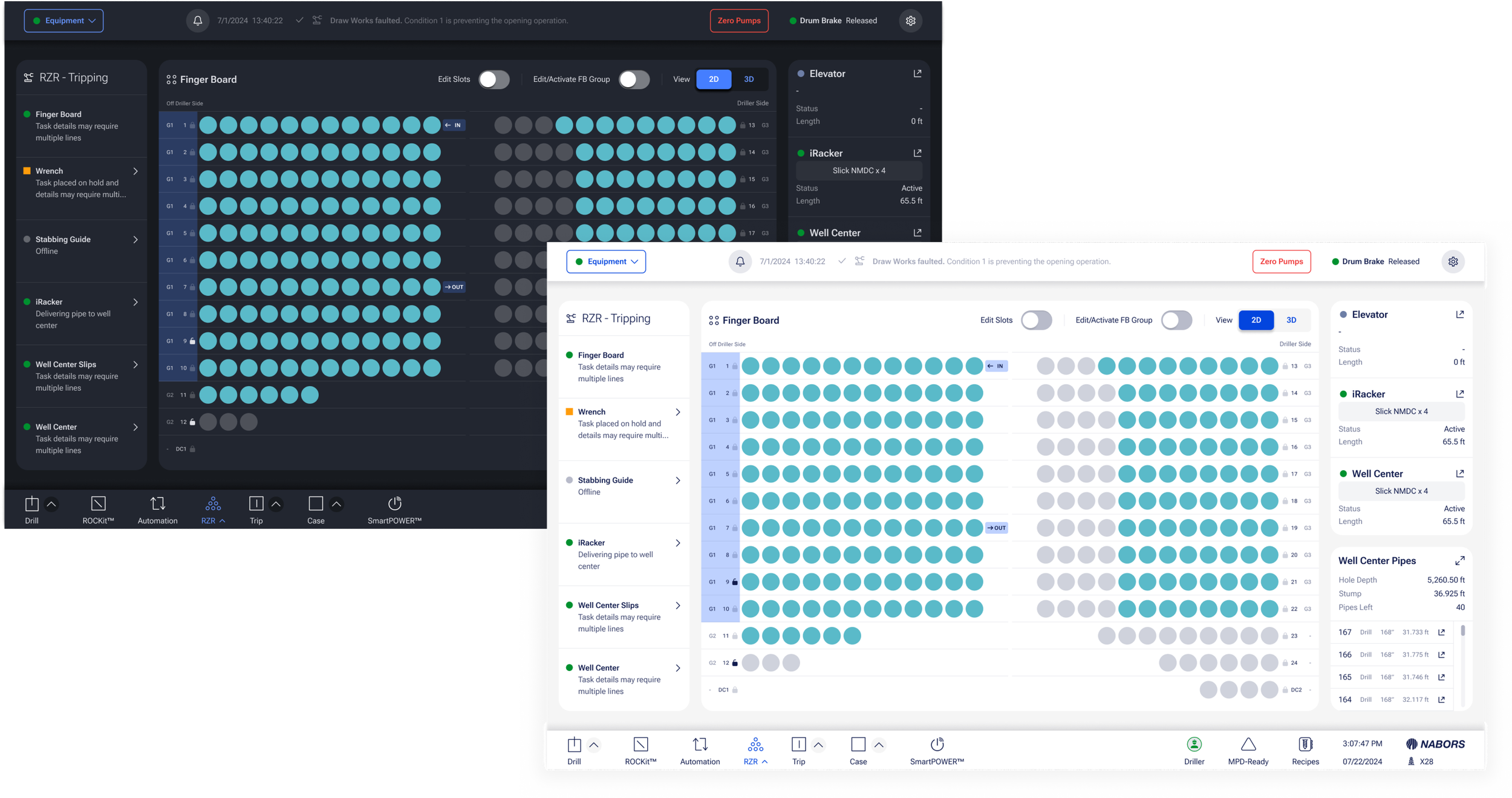

RZR SCREENS v1

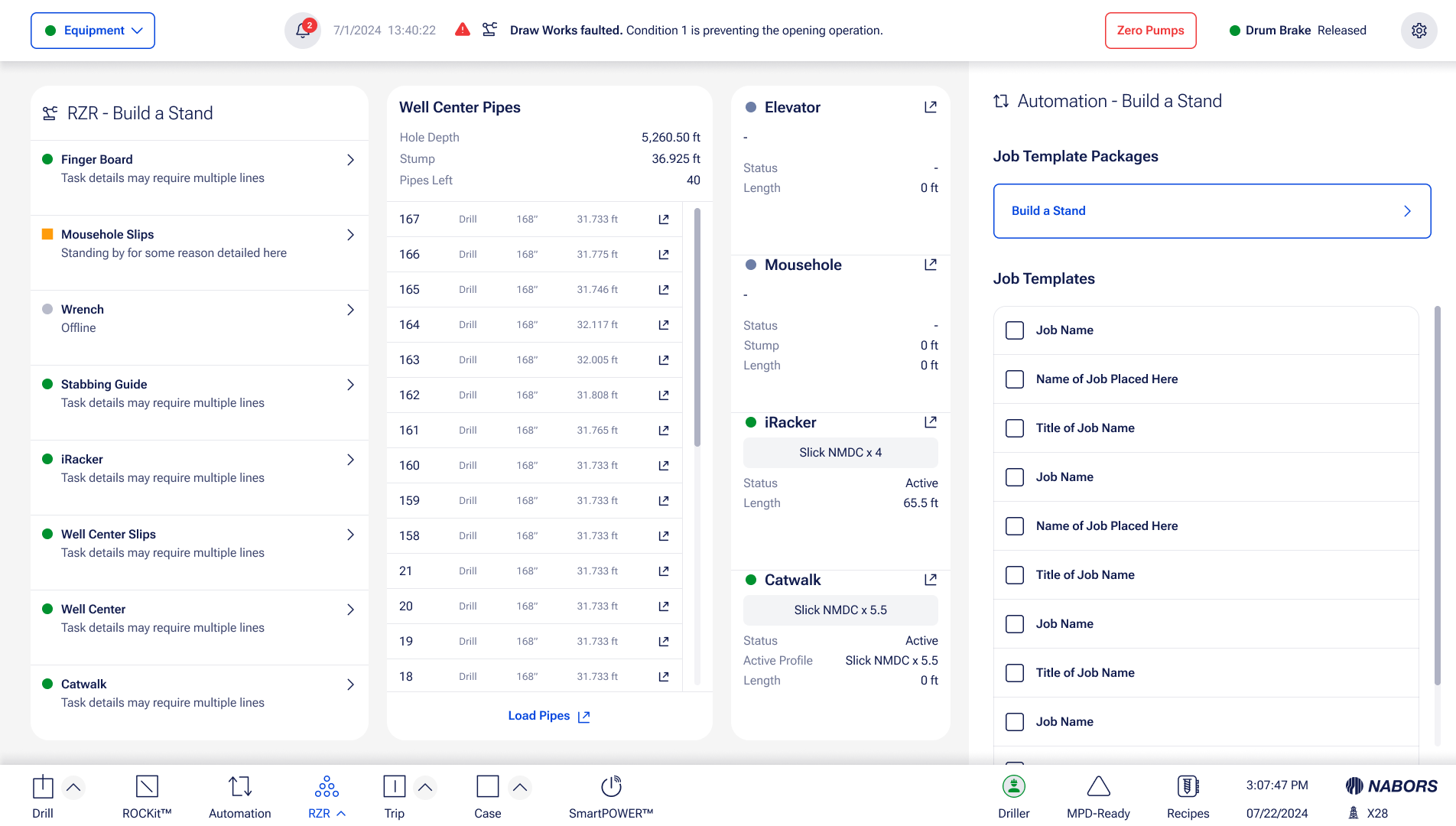

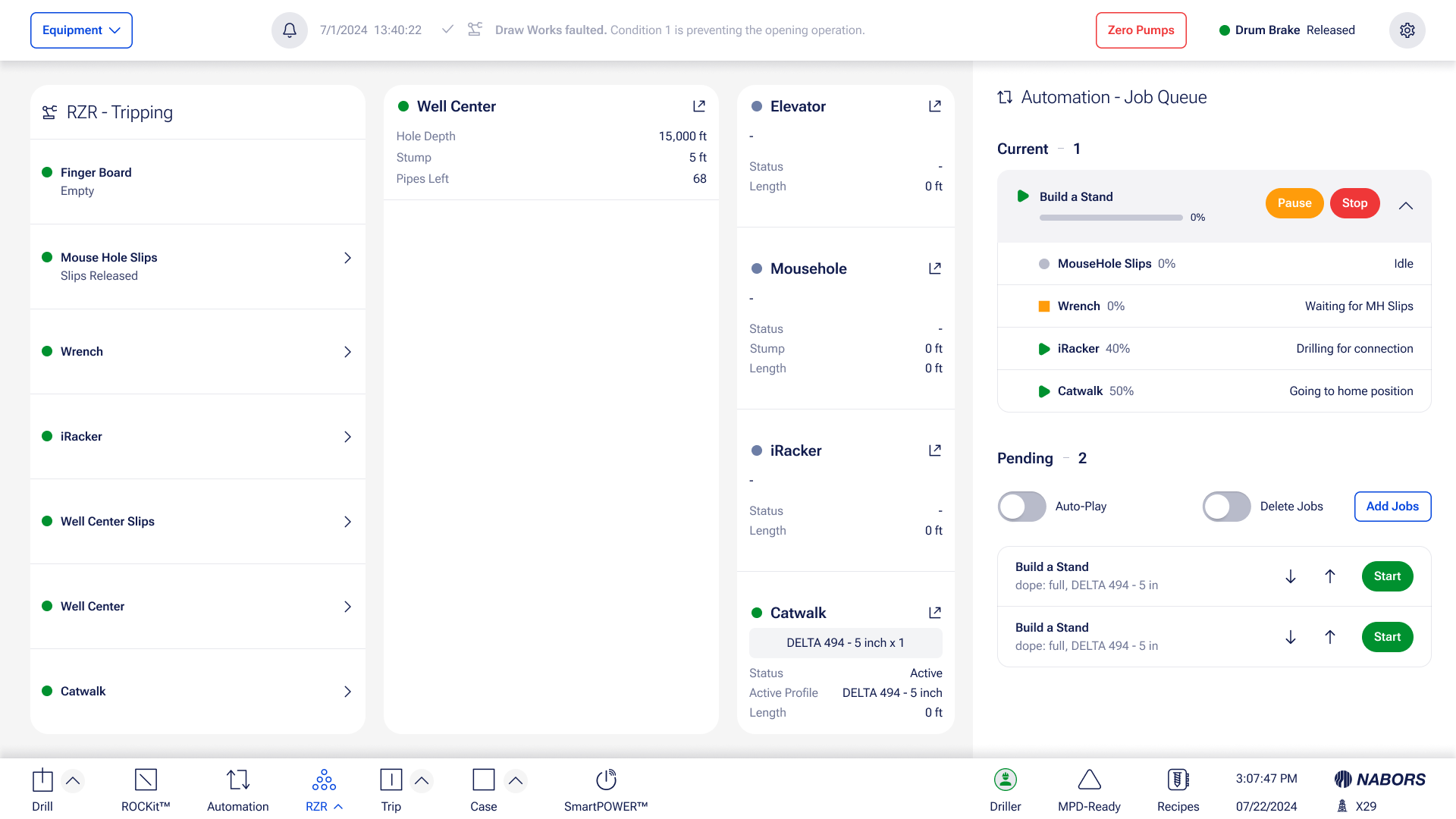

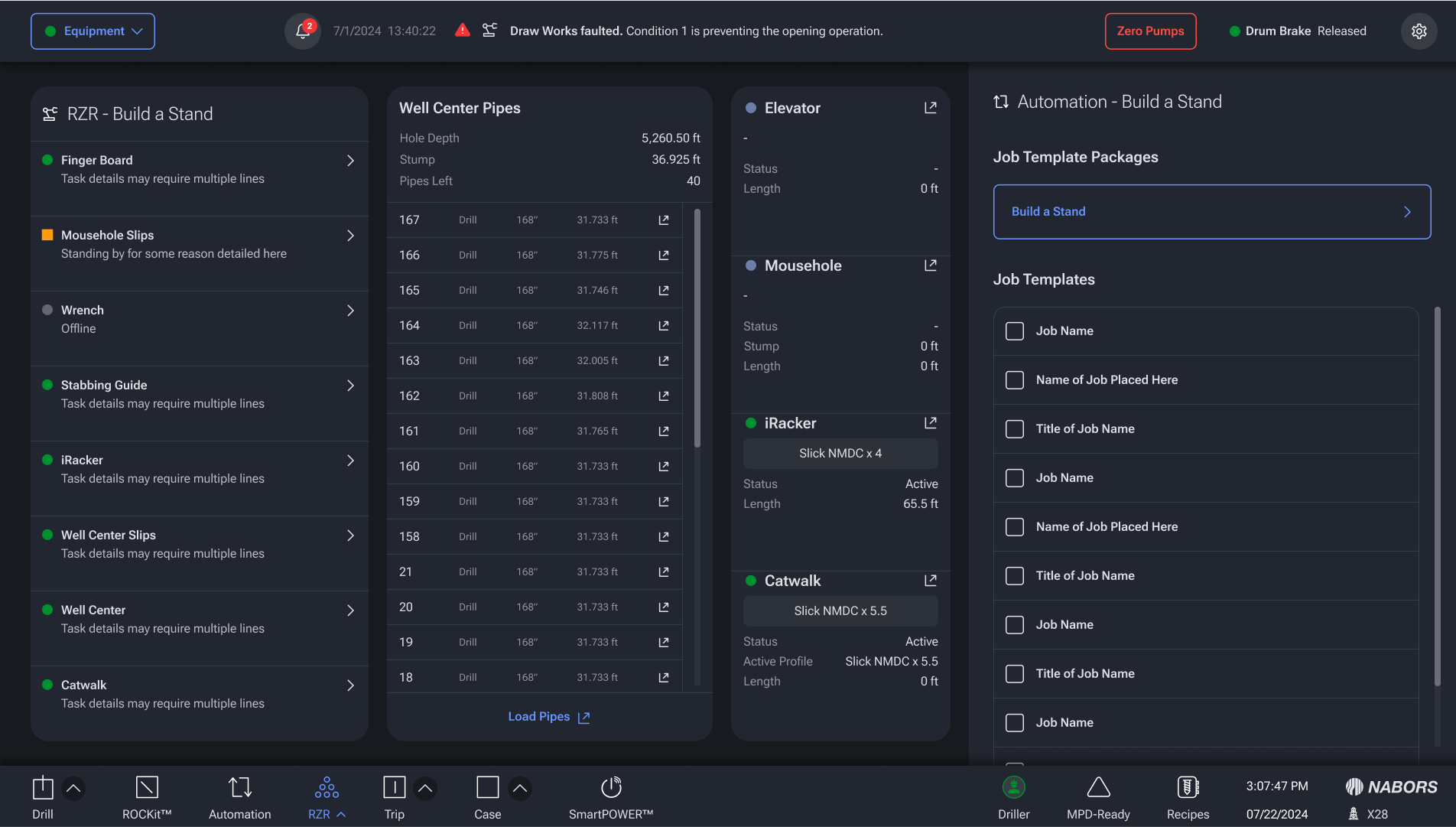

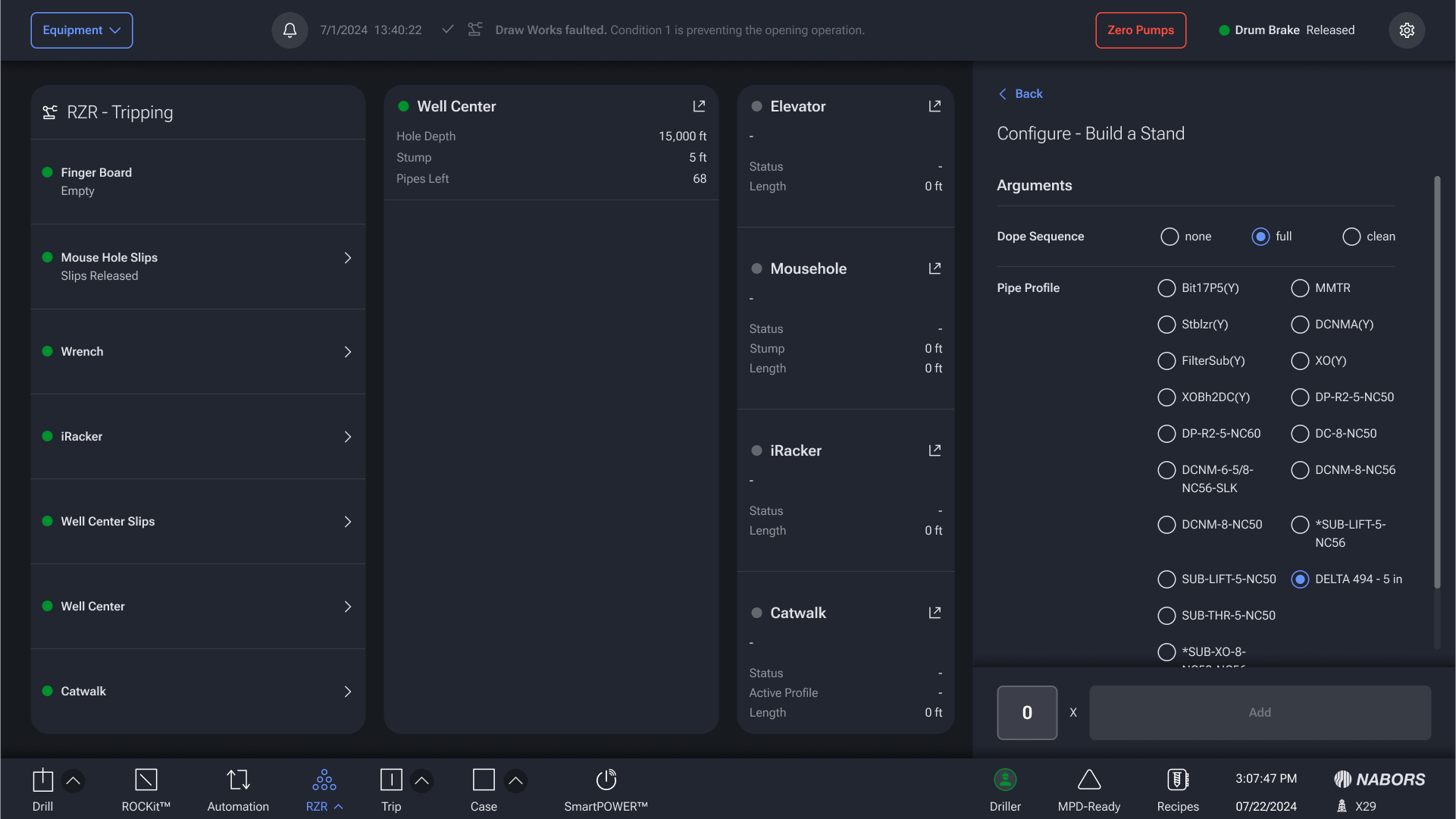

RZR Job Automation Screens (Light + Dark Mode)

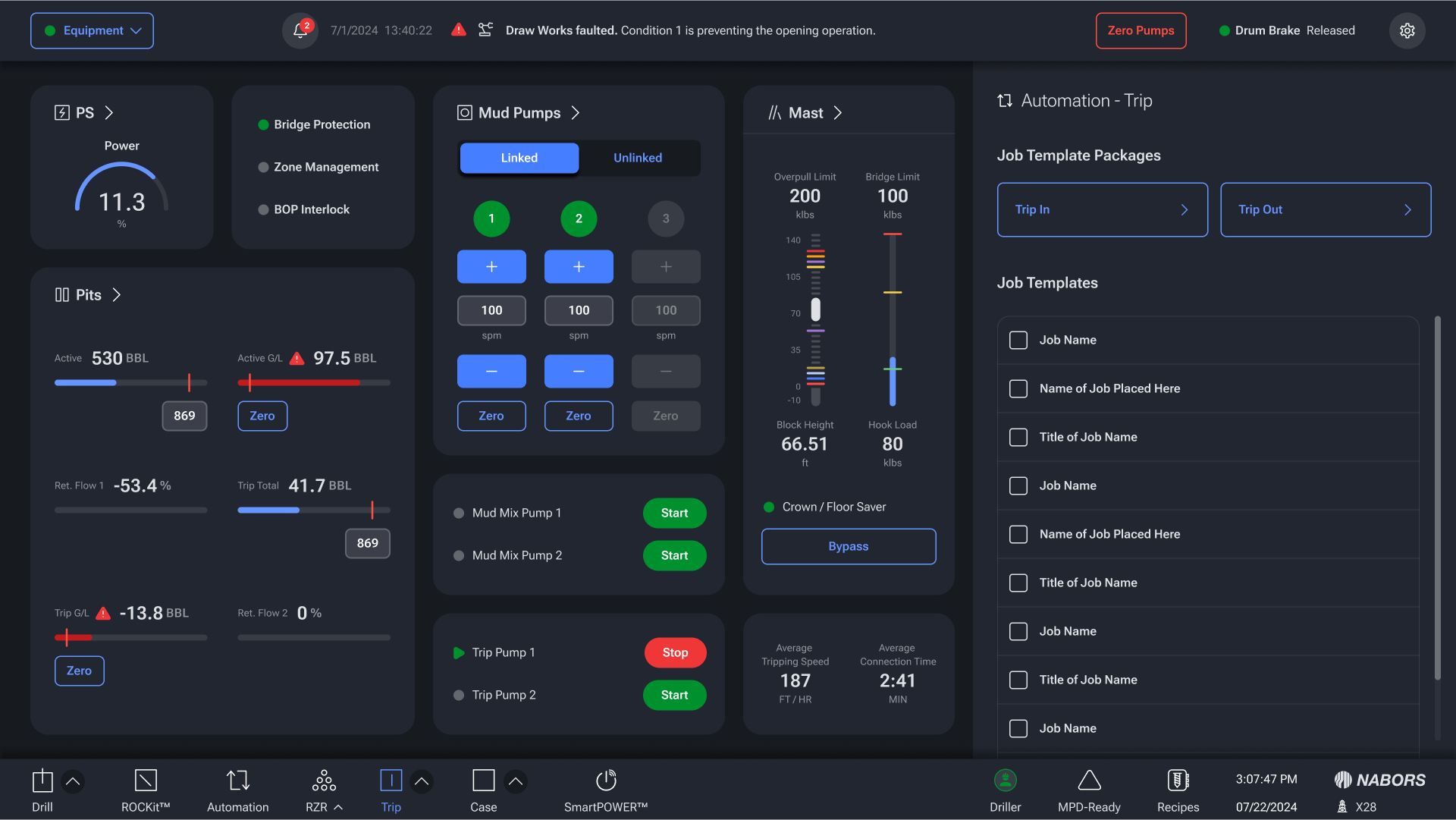

We grouped large tasks like Building a Stand, Laying Down Pipe, Tripping In, and Tripping Out into new screens and added them under the RZR nav in the bottom navigation. In all screens an automation panel was created for highly complex configurations of job tasks to be carried out by individual machines. This allowed drillers to keep track of their current jobs running, add additional jobs to the queue and stop all jobs. The job template selection functioned similarly to an MP3 player.

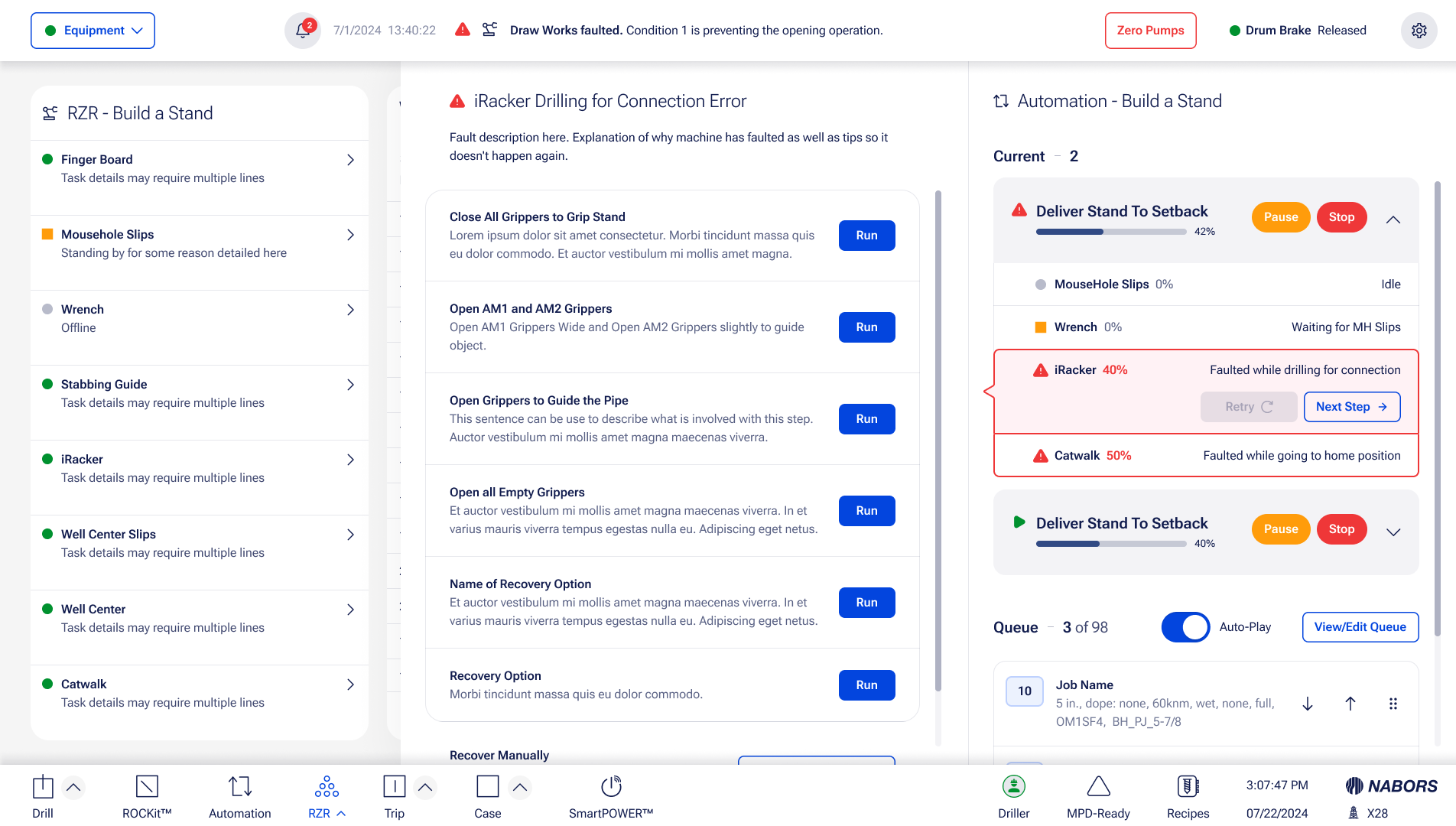

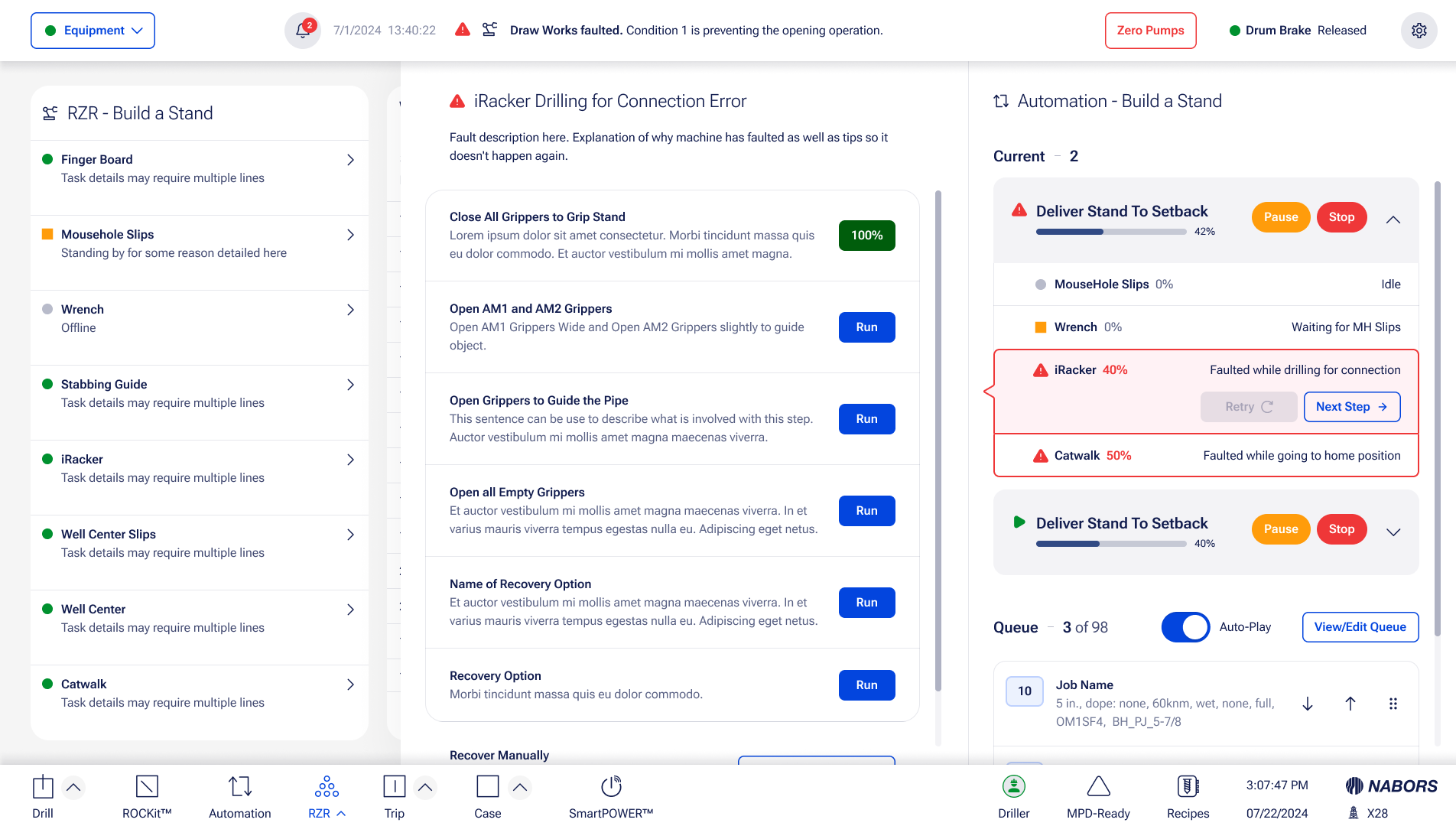

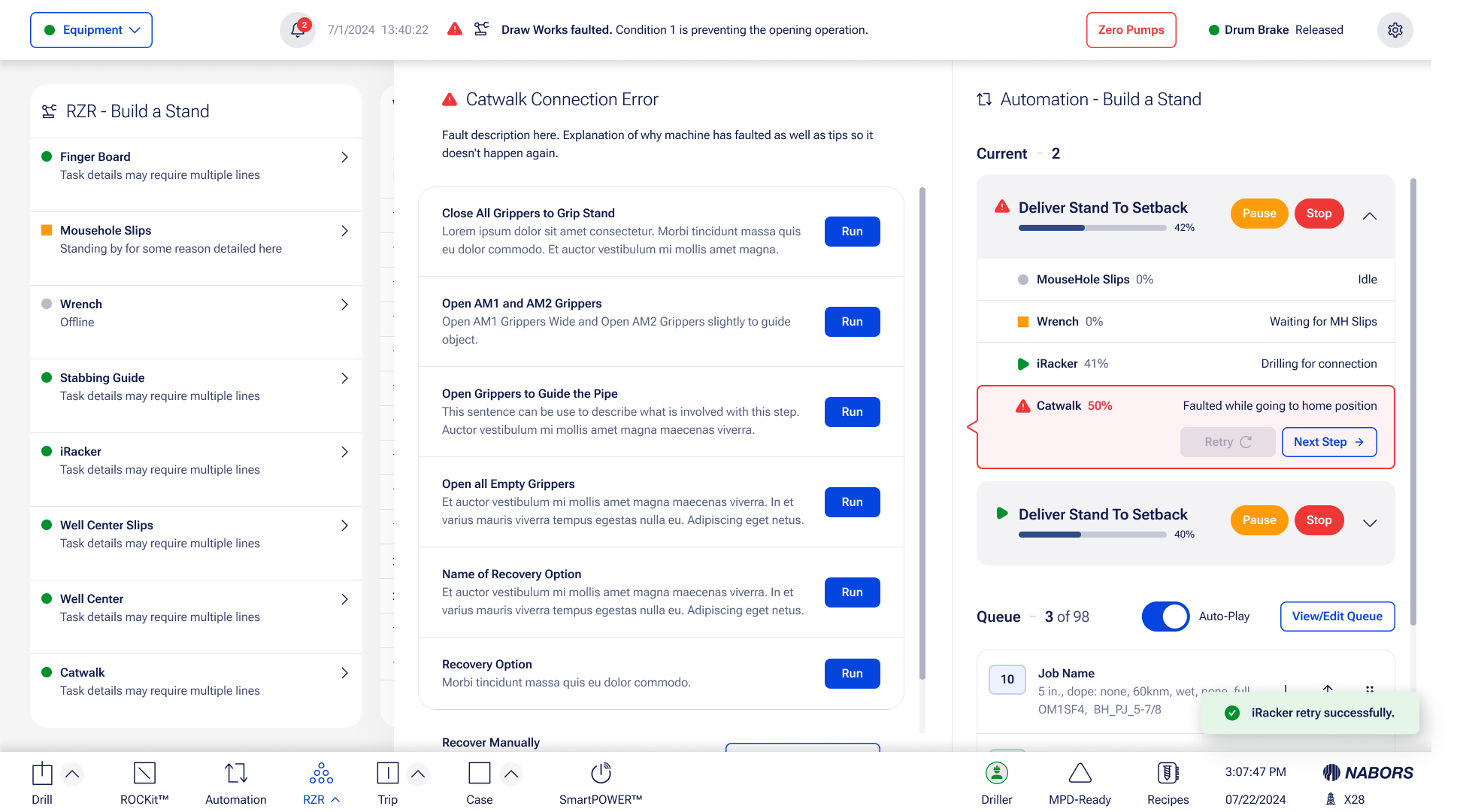

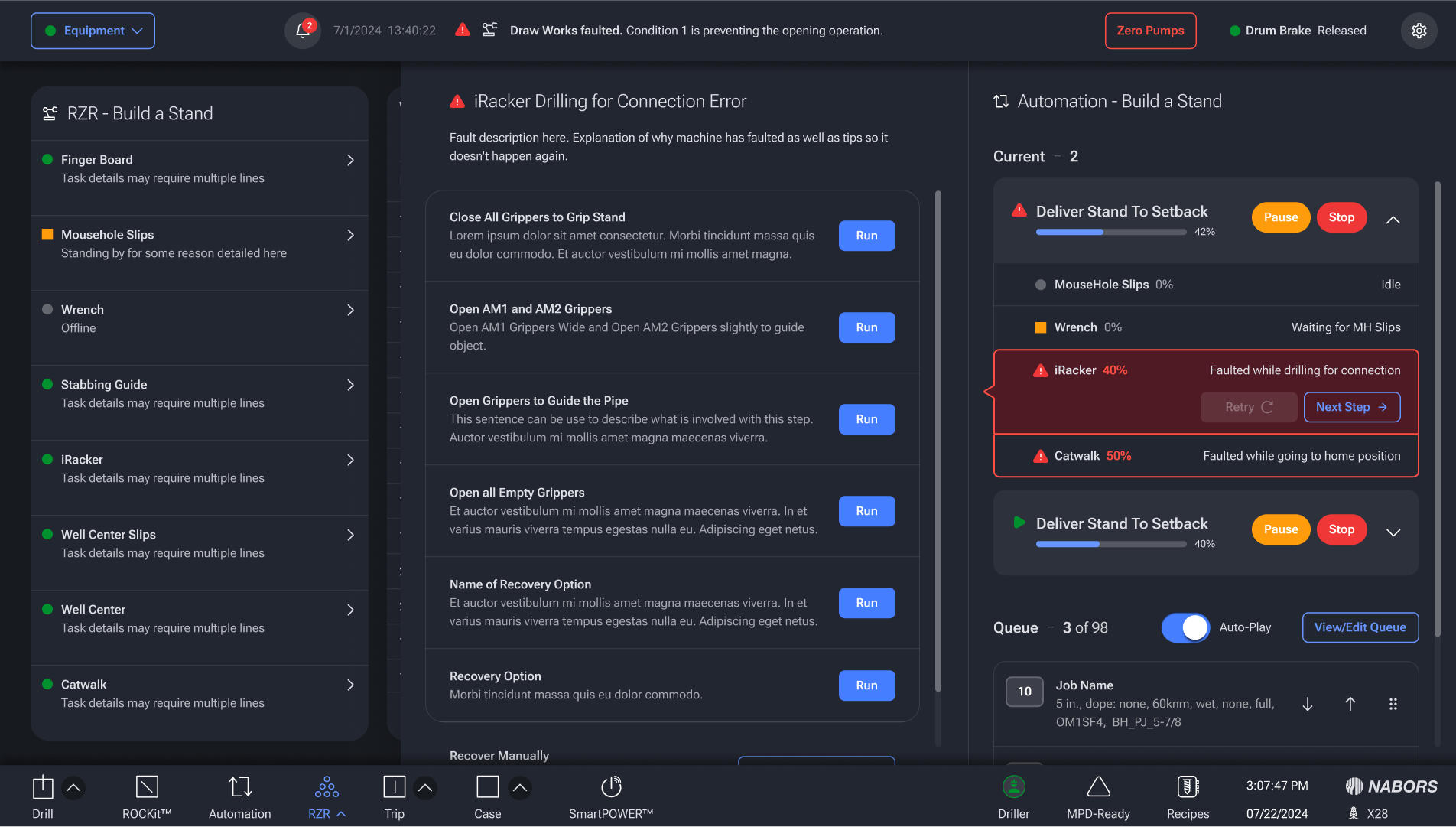

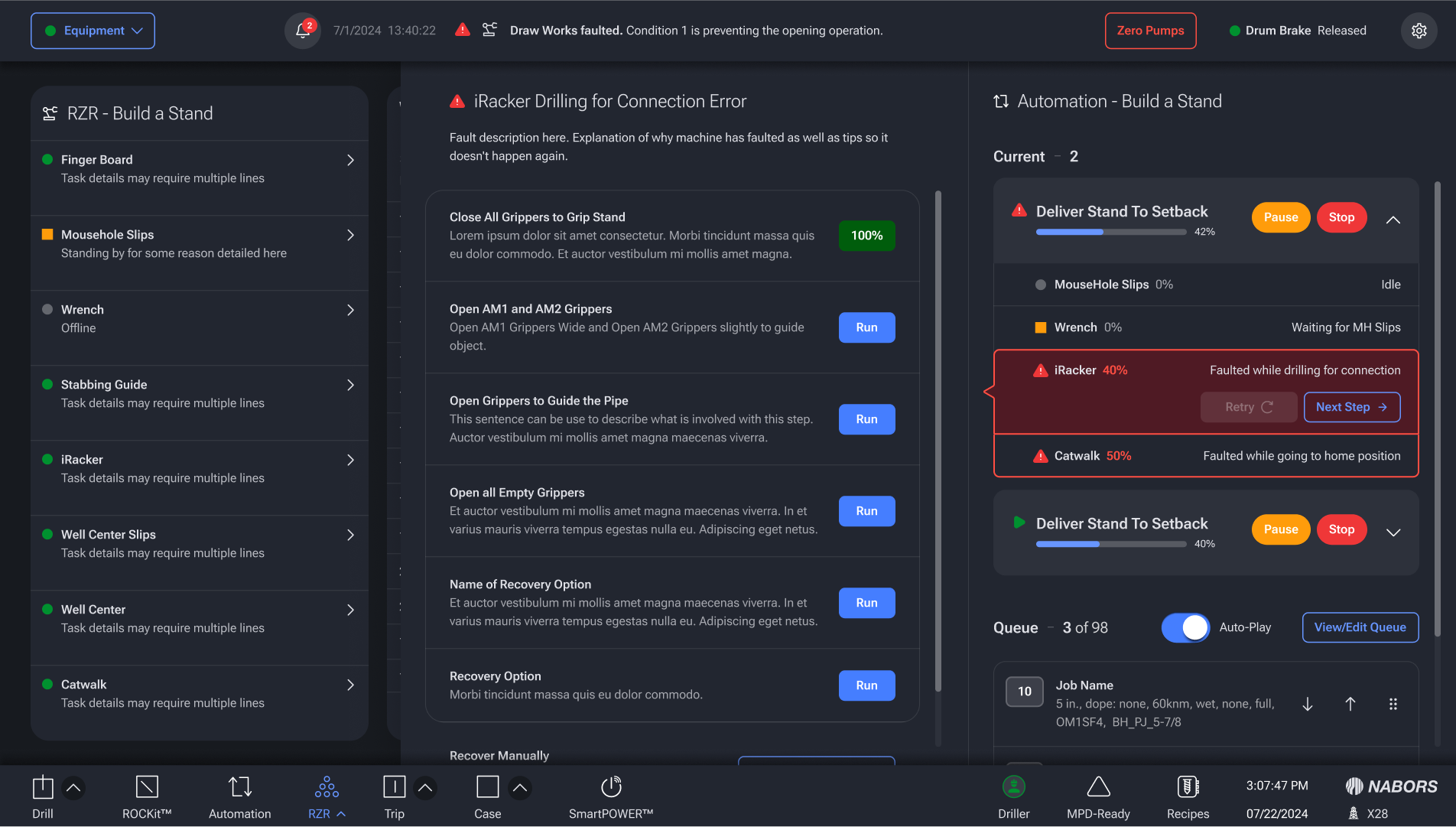

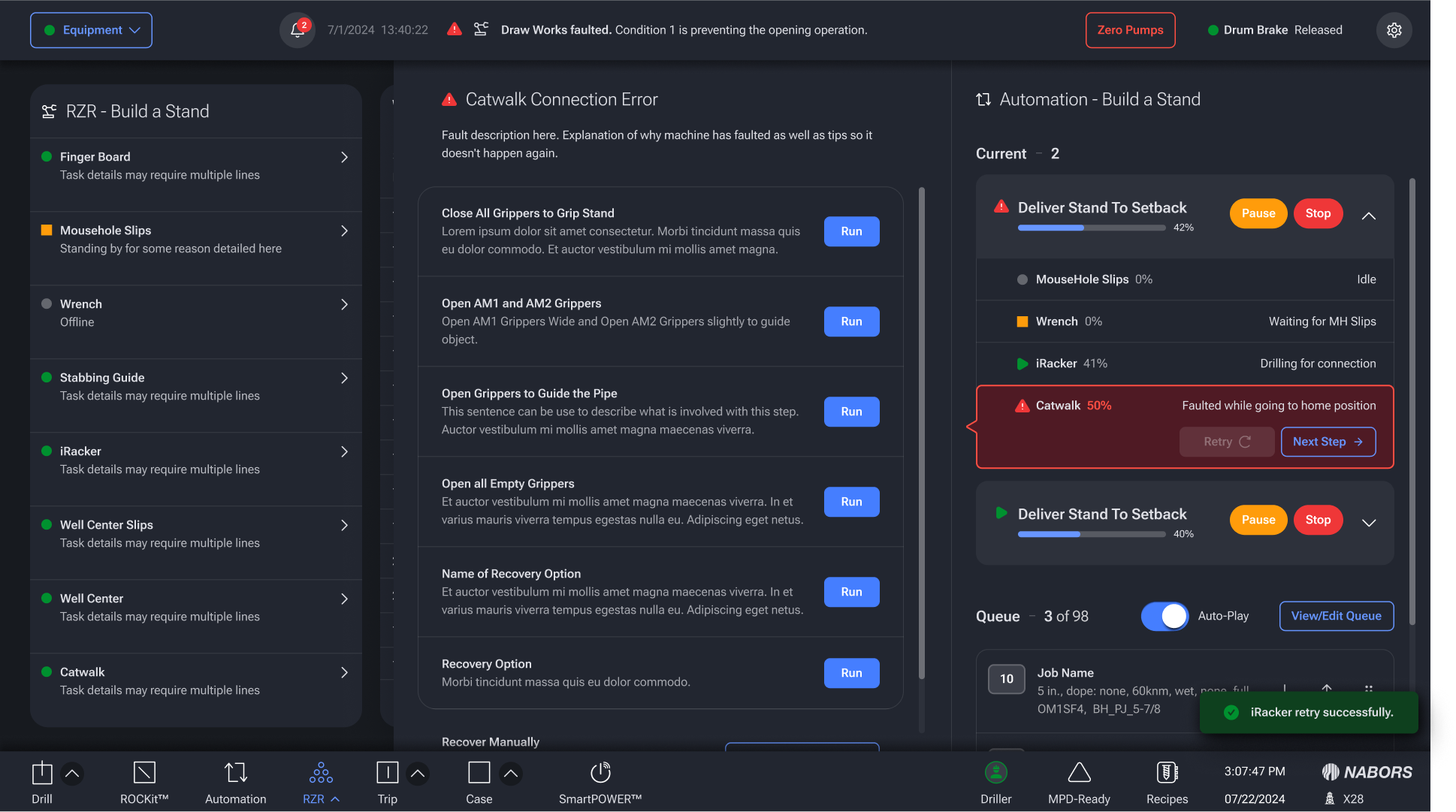

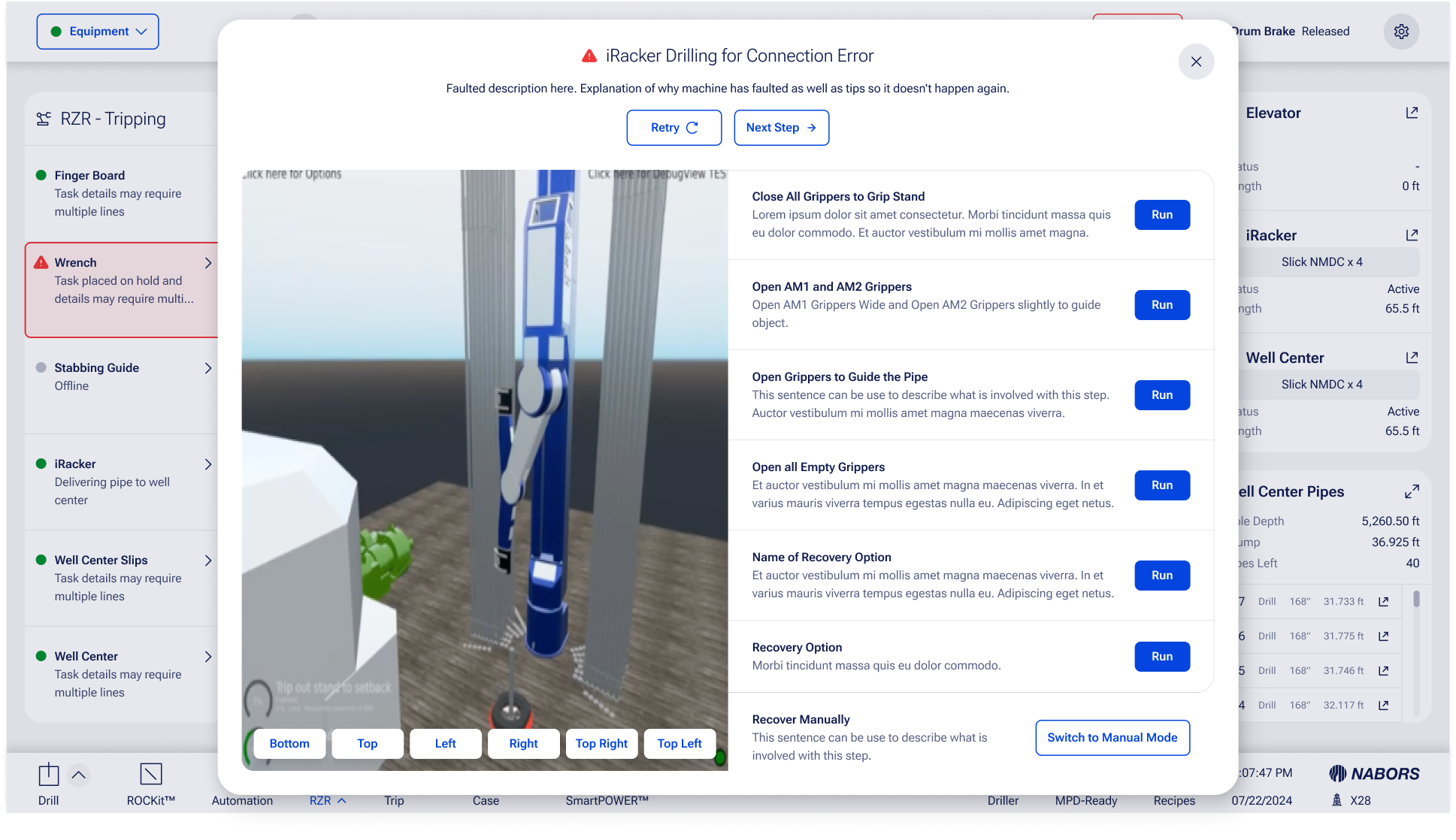

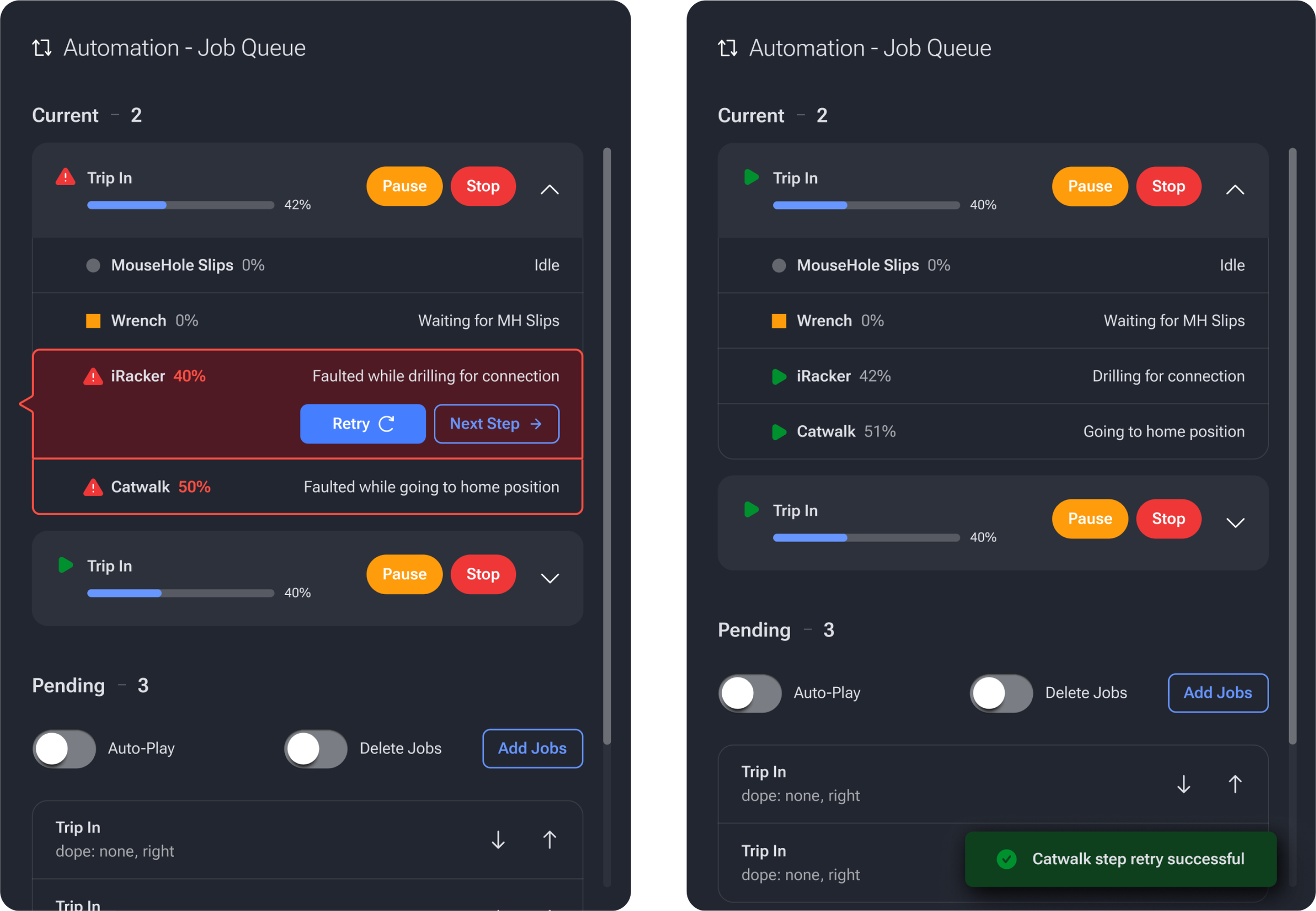

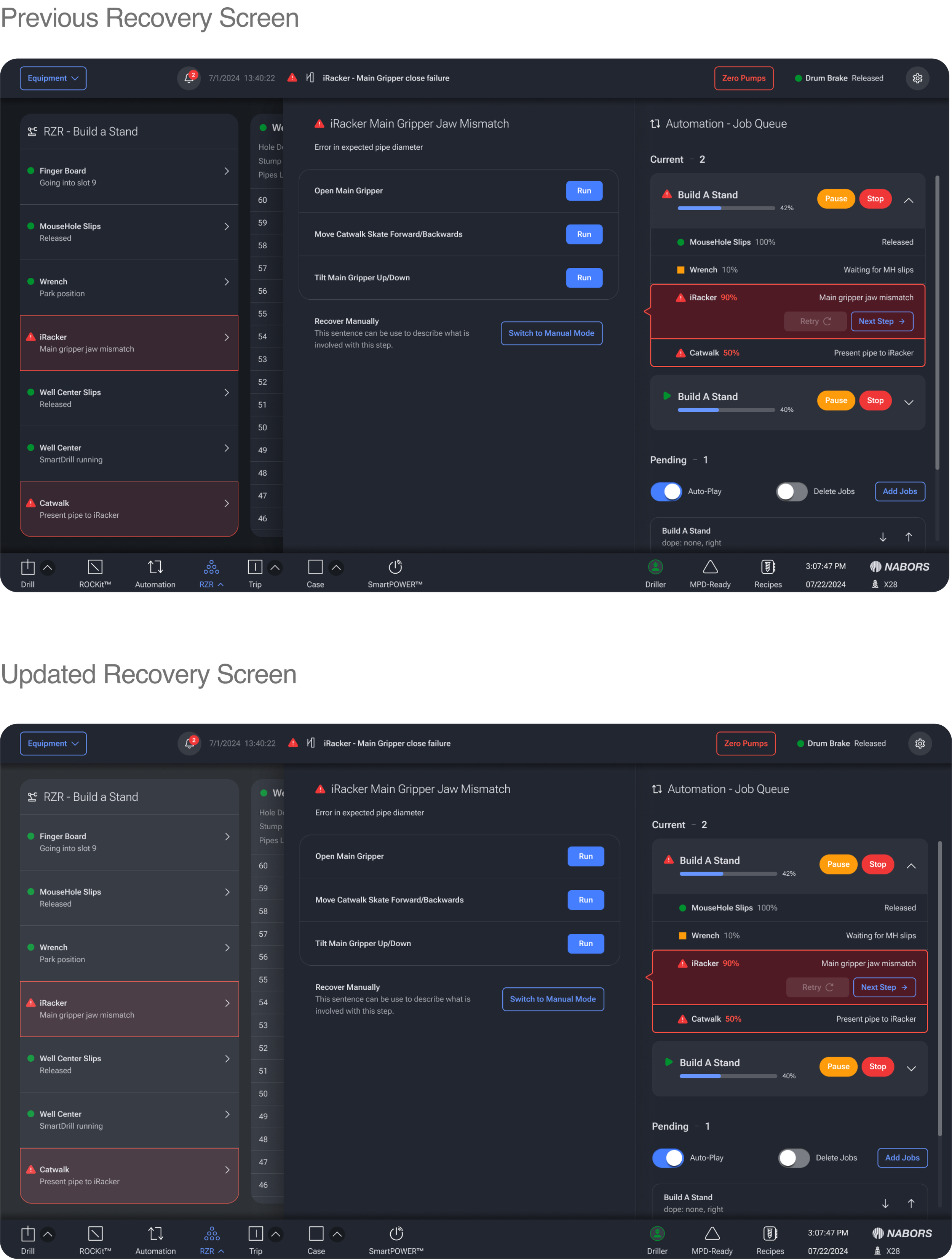

RZR Automation Recovery (Light + Dark Mode)

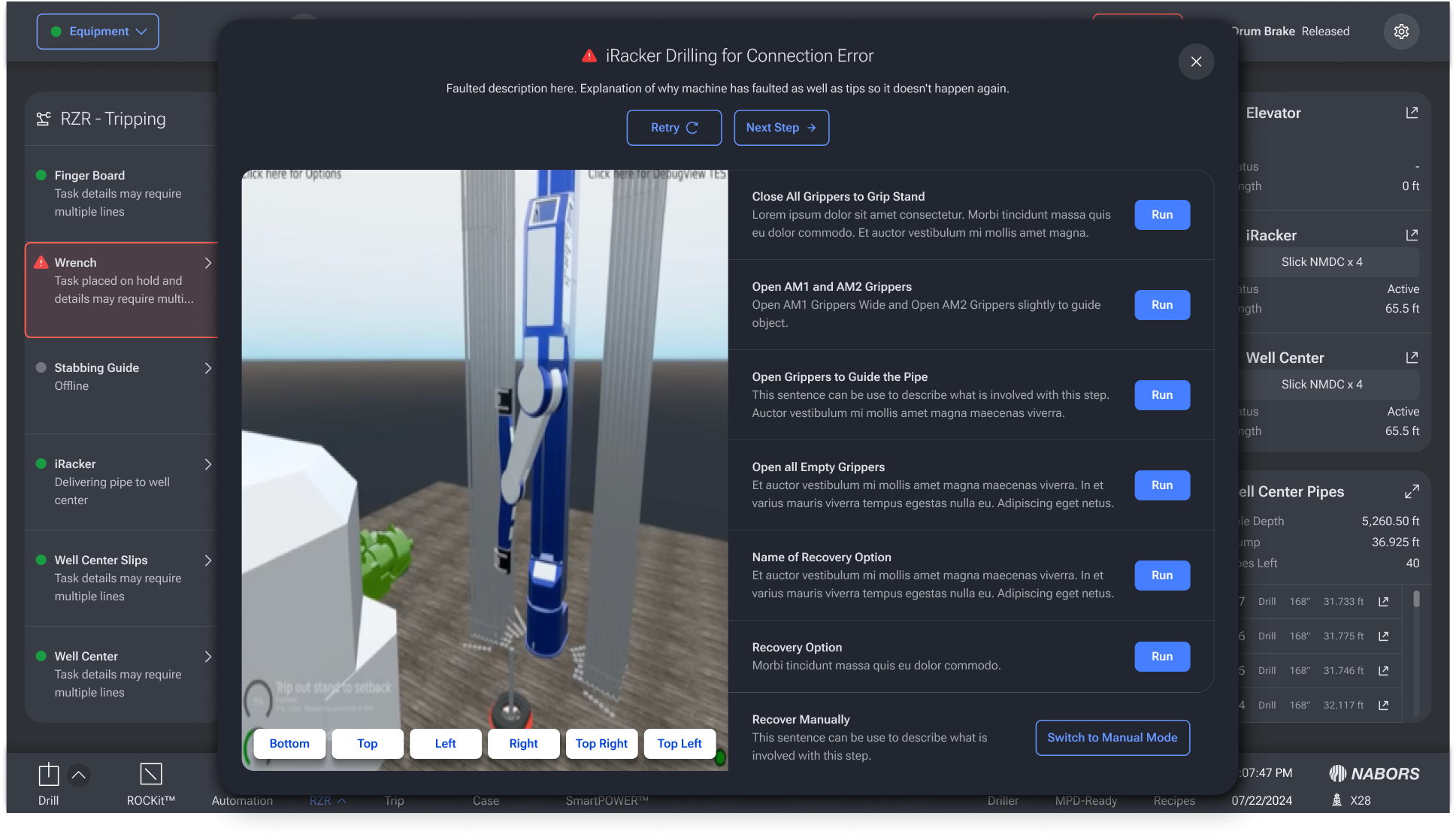

Automation recovery was integral to the platform’s utility. While the hope would be that every automated task isn’t met with errors, there still is the possibility that faulting occurs. When faulted, drillers would be presented with a number of solutions that they can try in order to get them out an error state and into recovery (job tasks and machines running normally). If all recovery options presented to the driller failed or were not possible due to equipment failures or environmental factors, we provided them with the ability to switch into manual mode where they could take over the operation with physical controls in the doghouse.

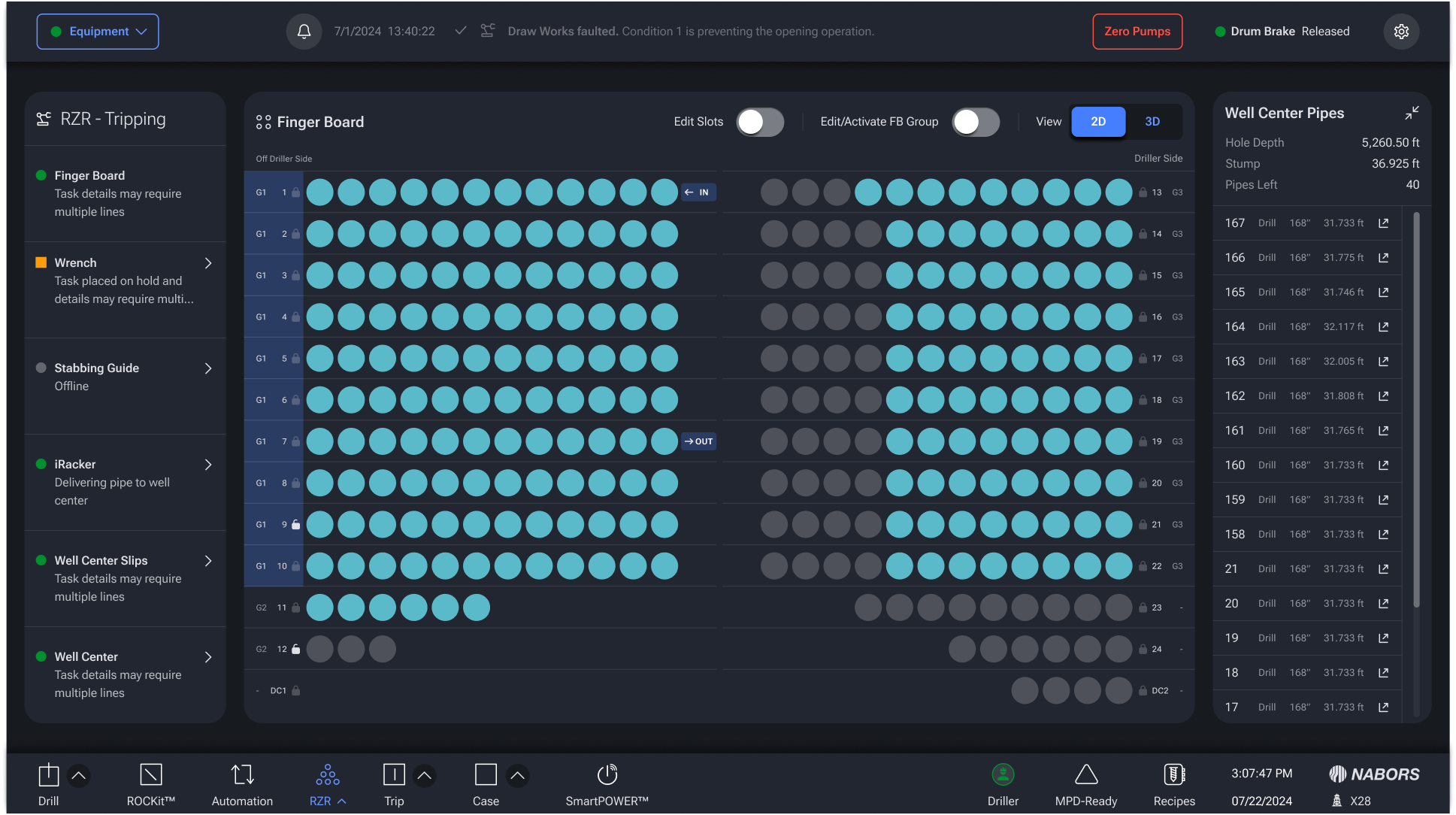

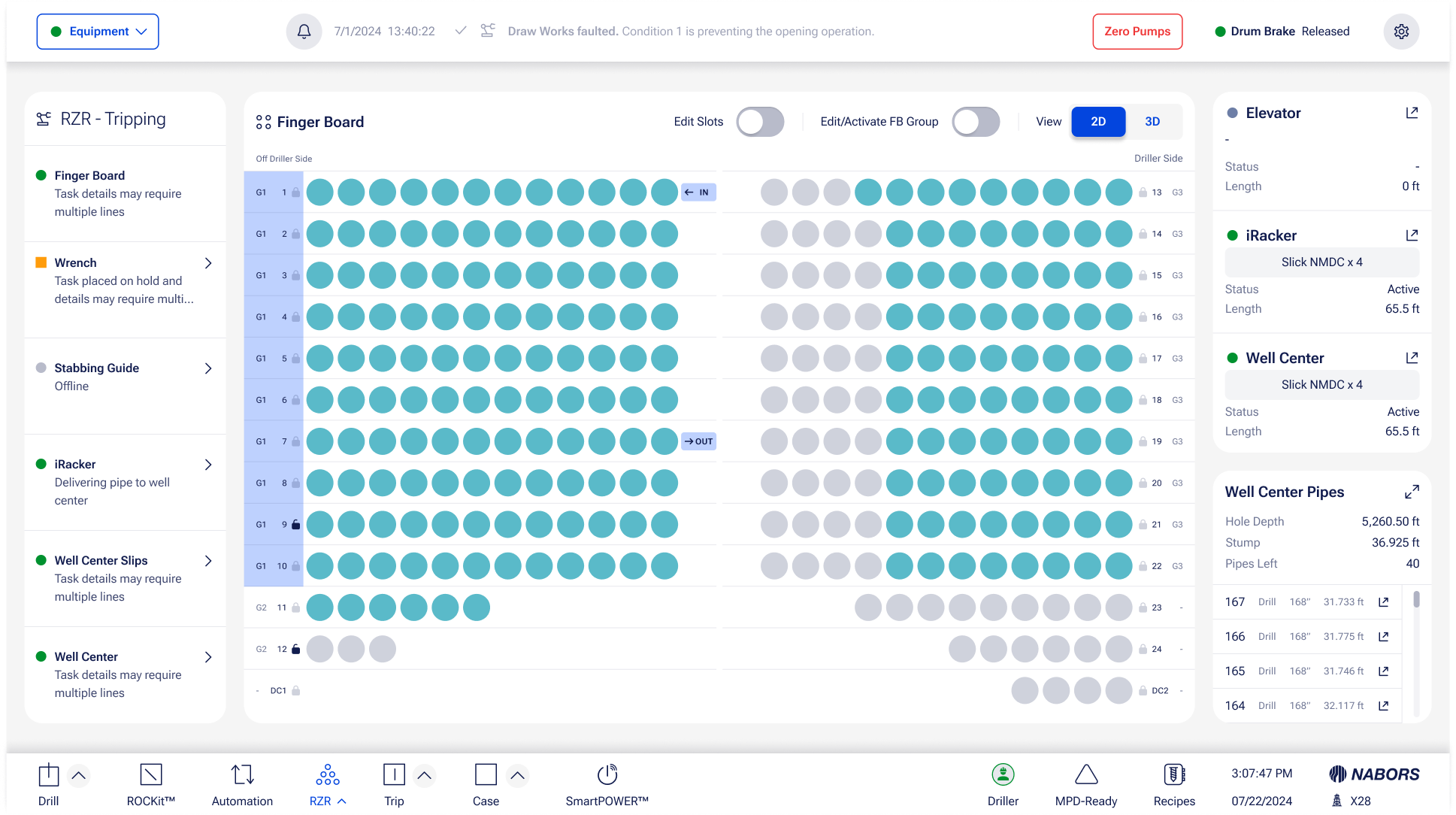

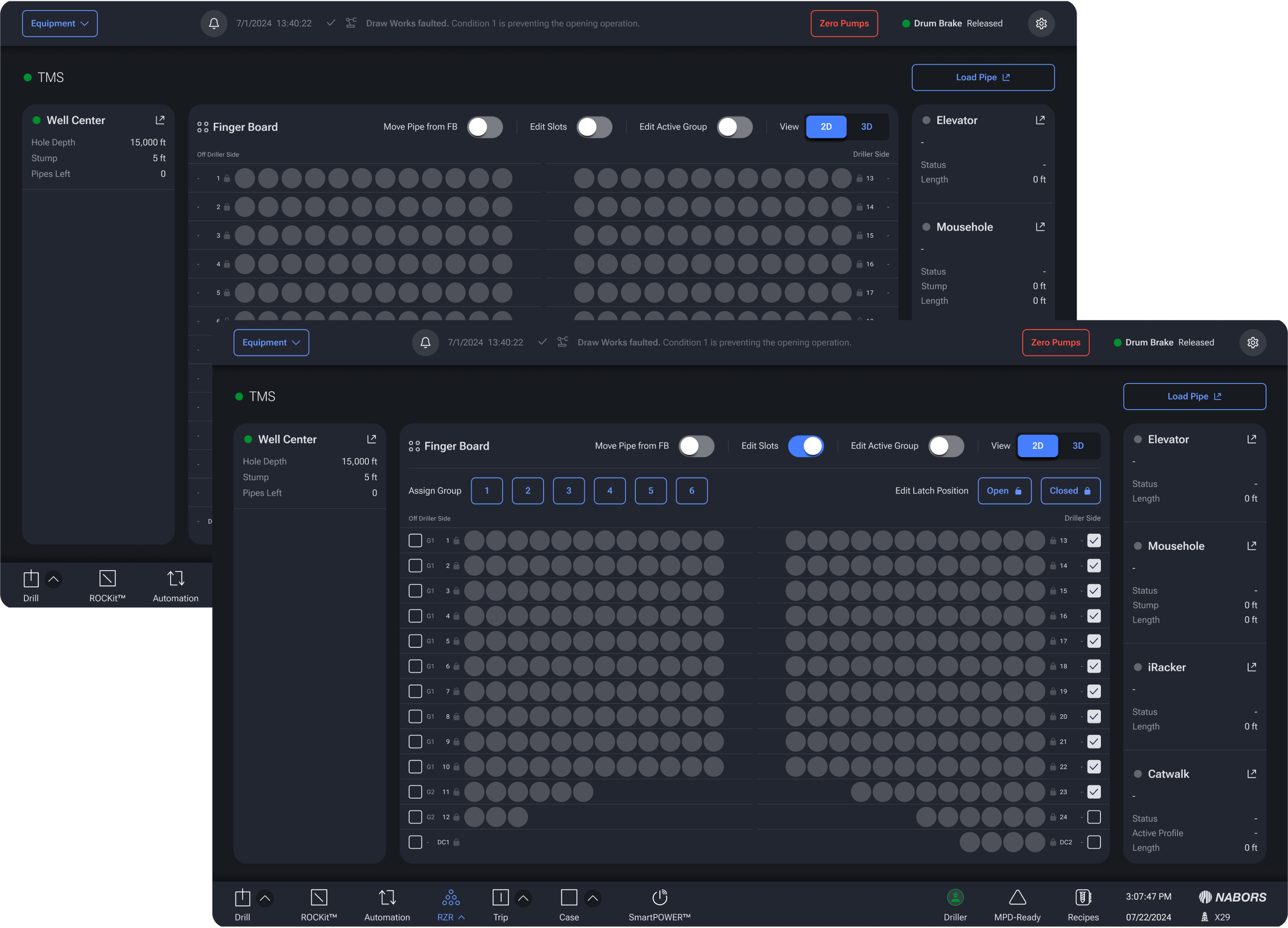

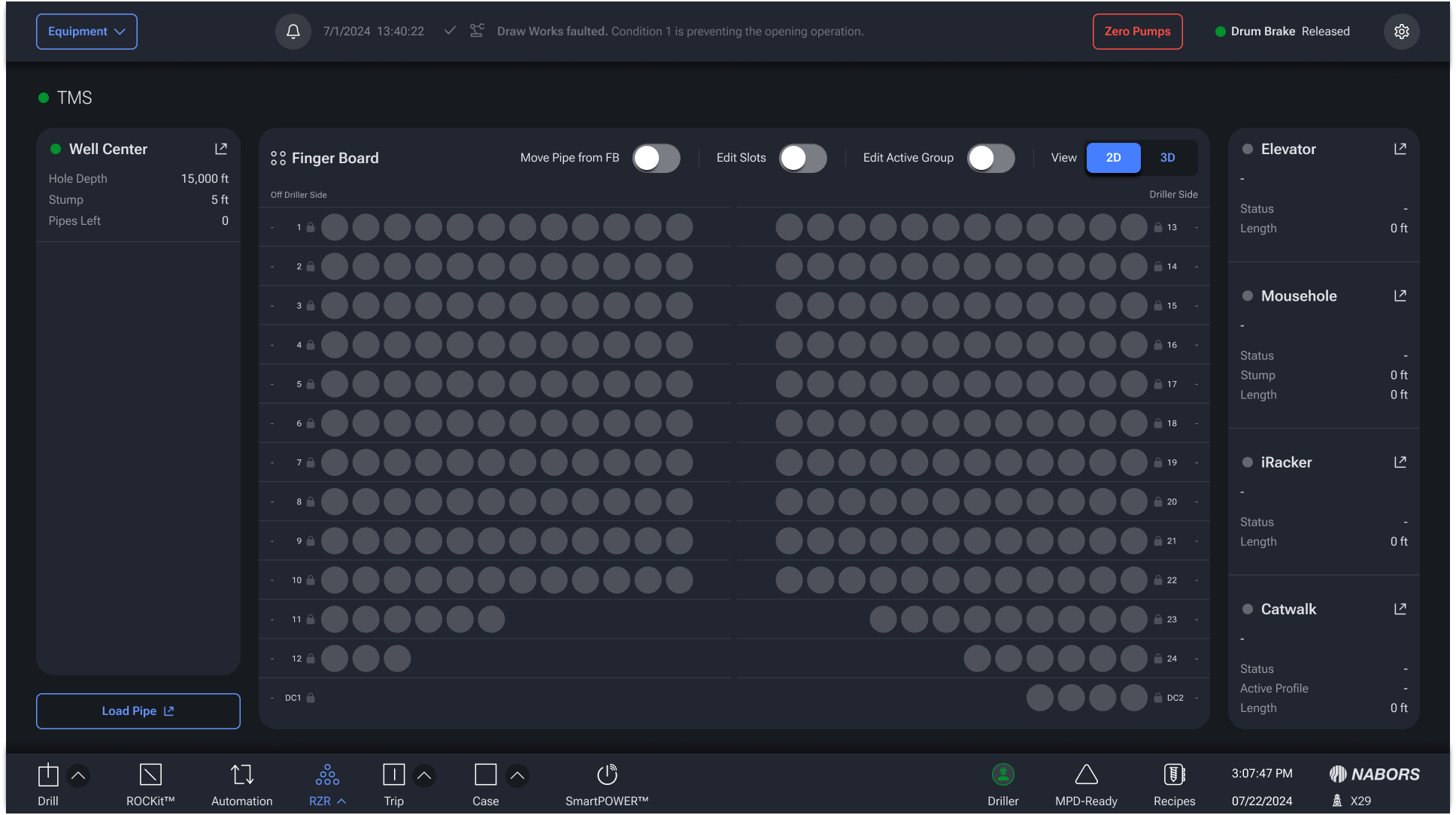

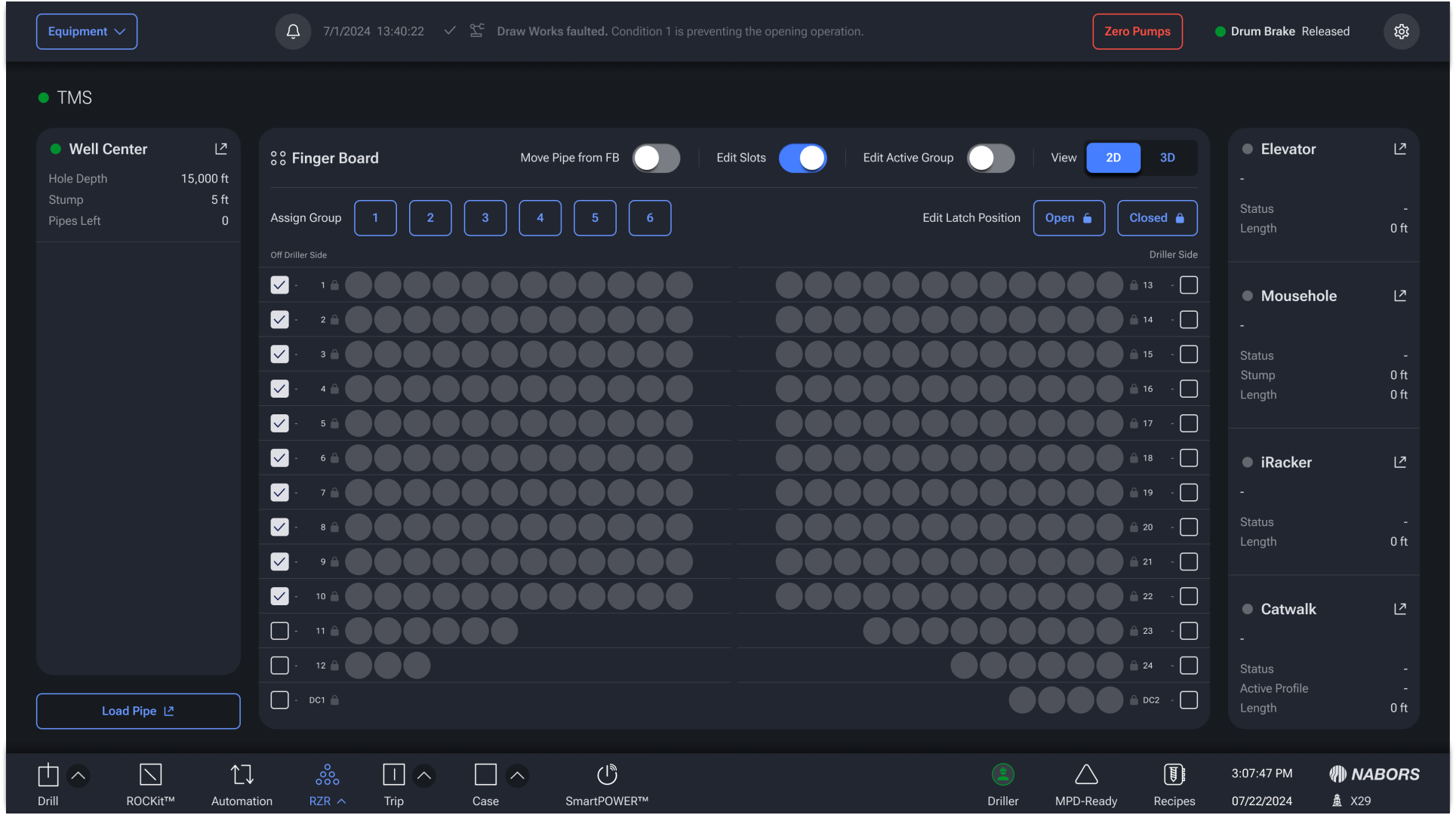

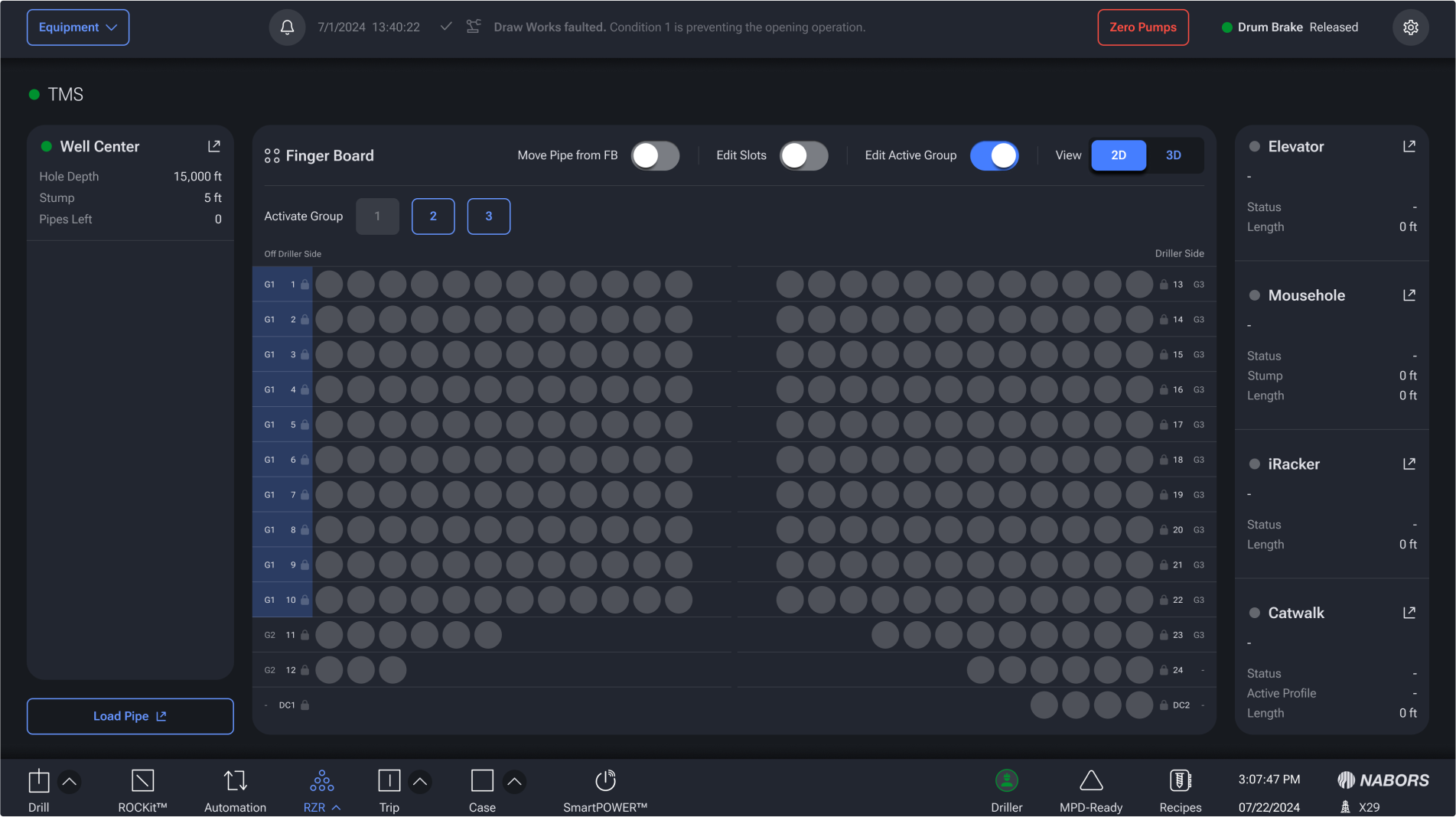

Similar to our build a stand and laydown a pipe screens under RZR, tripping in and out screens main component was the fingerboard (the area on the rig that houses all the pipes to be used for drilling). The fingerboard was critical to drillers both for automated tripping in and in individual equipment screens like the tubular management system (TMS).

RZR Trip (Light + Dark Mode)

We brought the automation panel into SmartROS (the operating system) which had the same framework as selecting jobs like Build a Stand or Laydown Pipe. Drillers were able to choose their automation tasks that add to their expansive job queue and monitor the automation as it was being performed.

SmartROS Trip (Light + Dark Mode)

We updated the overall OS notification system to now include any collision alerts that drillers needed to be aware of when performing tasks. If collisions or errors occurred, the top navigation dropdown would alert drillers what the issue was as well as give them the breakdown and option to recover from the error.

Notifications ie., Recovery (Dark Mode)

Tubular Management System -TMS (Dark Mode)

The tubular management system or TMS is critical for drillers as they first begin to trip in (start the entirety of the drilling process) or trip out (when drilling has finished and they need to move locations). The TMS acts as an accounting of all pipes in within the fingerboard that will be picked up the iRacker (a mechanical robotic arm that grabs the pipe and moves it to where it wants to go). As we looked to enhancing the previous TMS screens to fit within our new platform the decision was made to change the orientation of the fingerboard digitally represented from vertical to horizontal as well as provide an easier means of grouping full rows together. We also changed indicators for the direction pipes were moving out of rows.

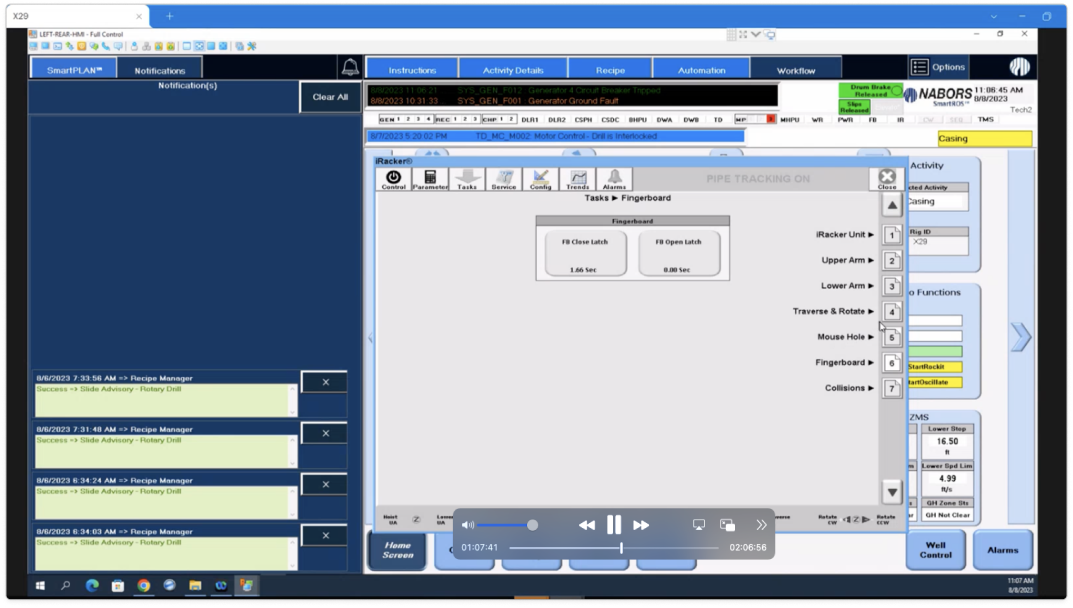

Previous TMS Screens

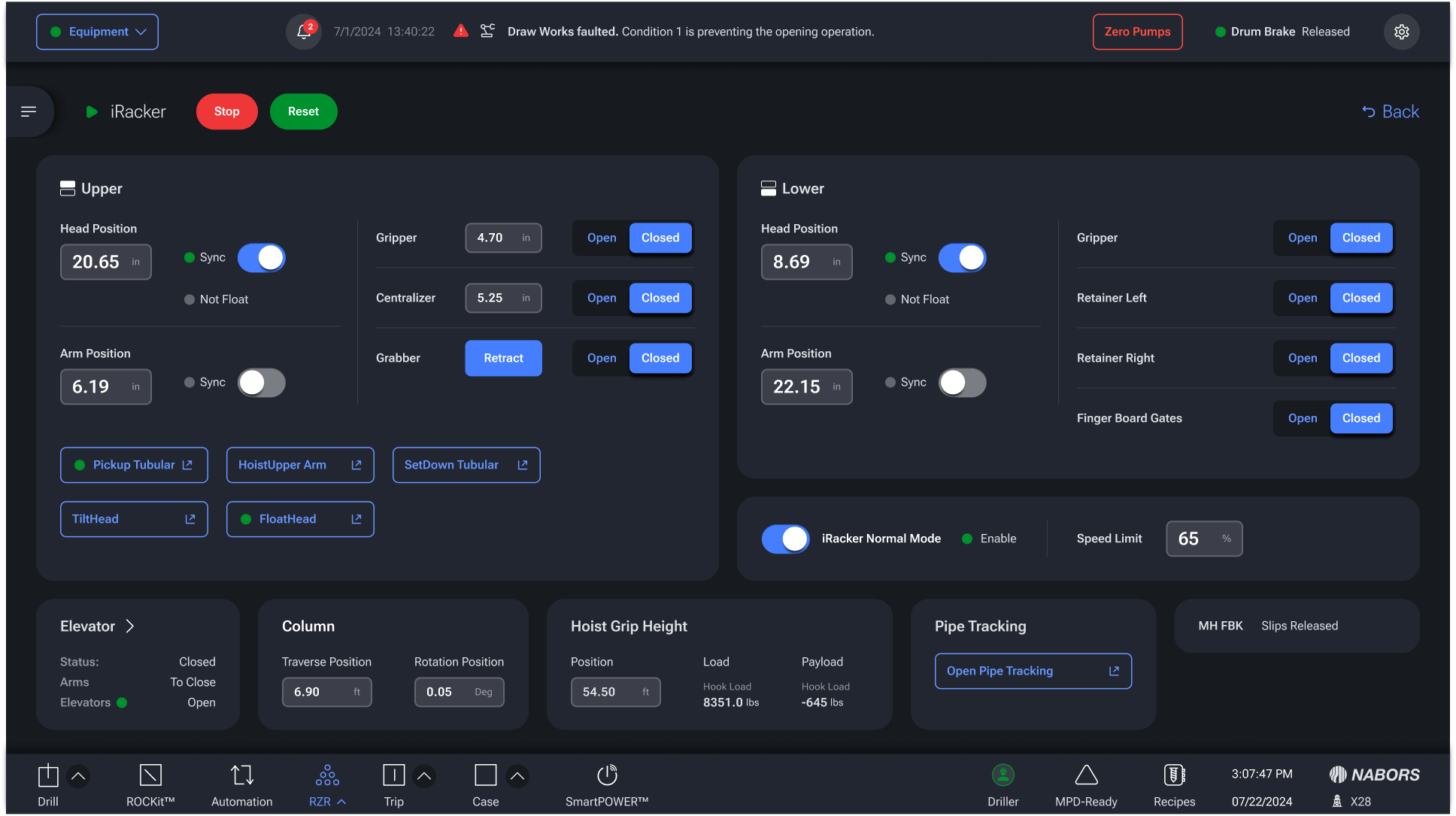

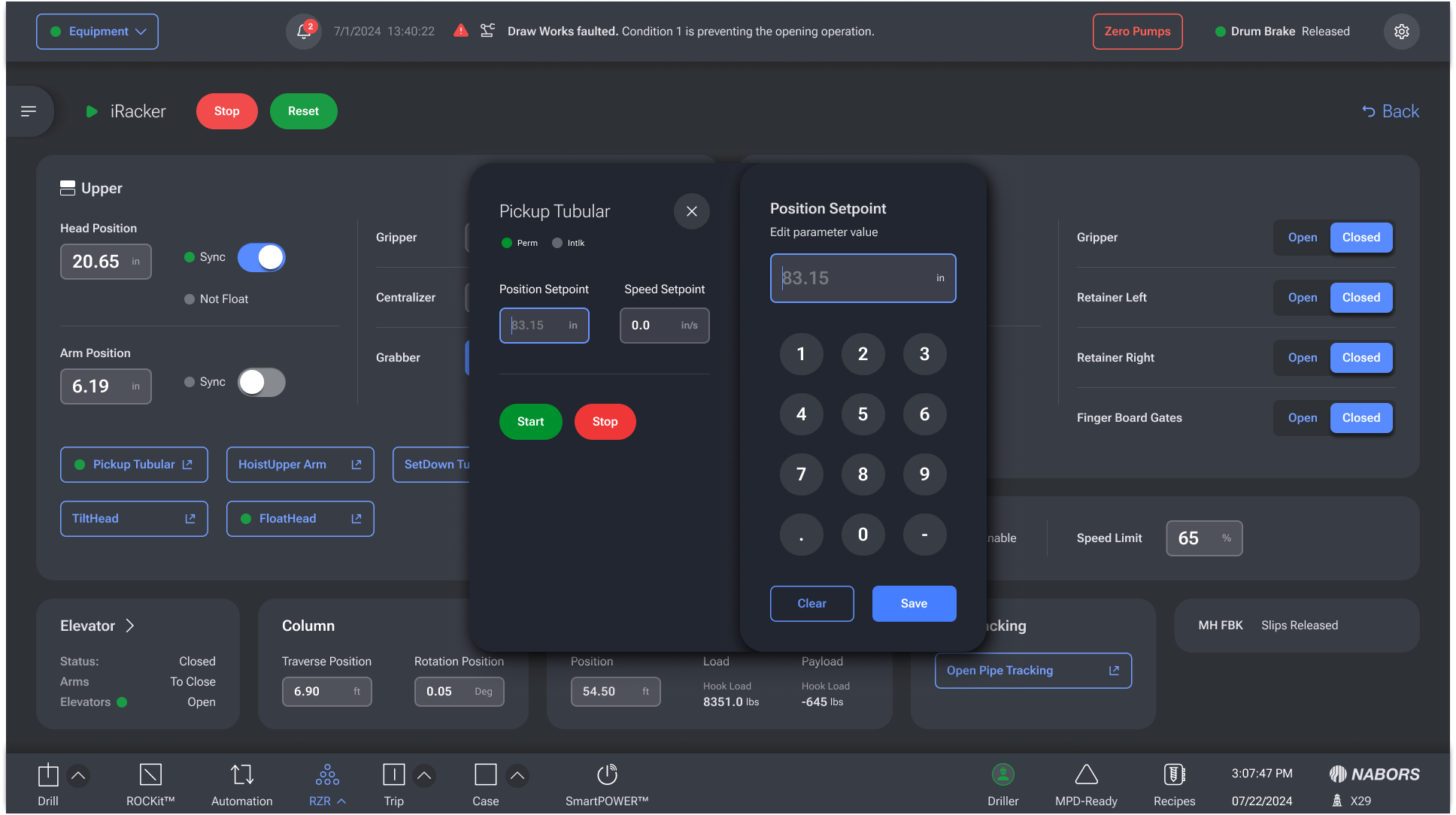

Equipment screens like iRacker were critical to drillers being able to effectively monitor and track what was happening with the equipment. iRacker alone had about 10+ different screens, each having duplicative information or controls on each. To solve for this, we consolidated multiple screens into a single screen and leveraged modals for additional functionality.

iRacker (Light + Dark Mode)

Previous iRacker (10+ Screens)

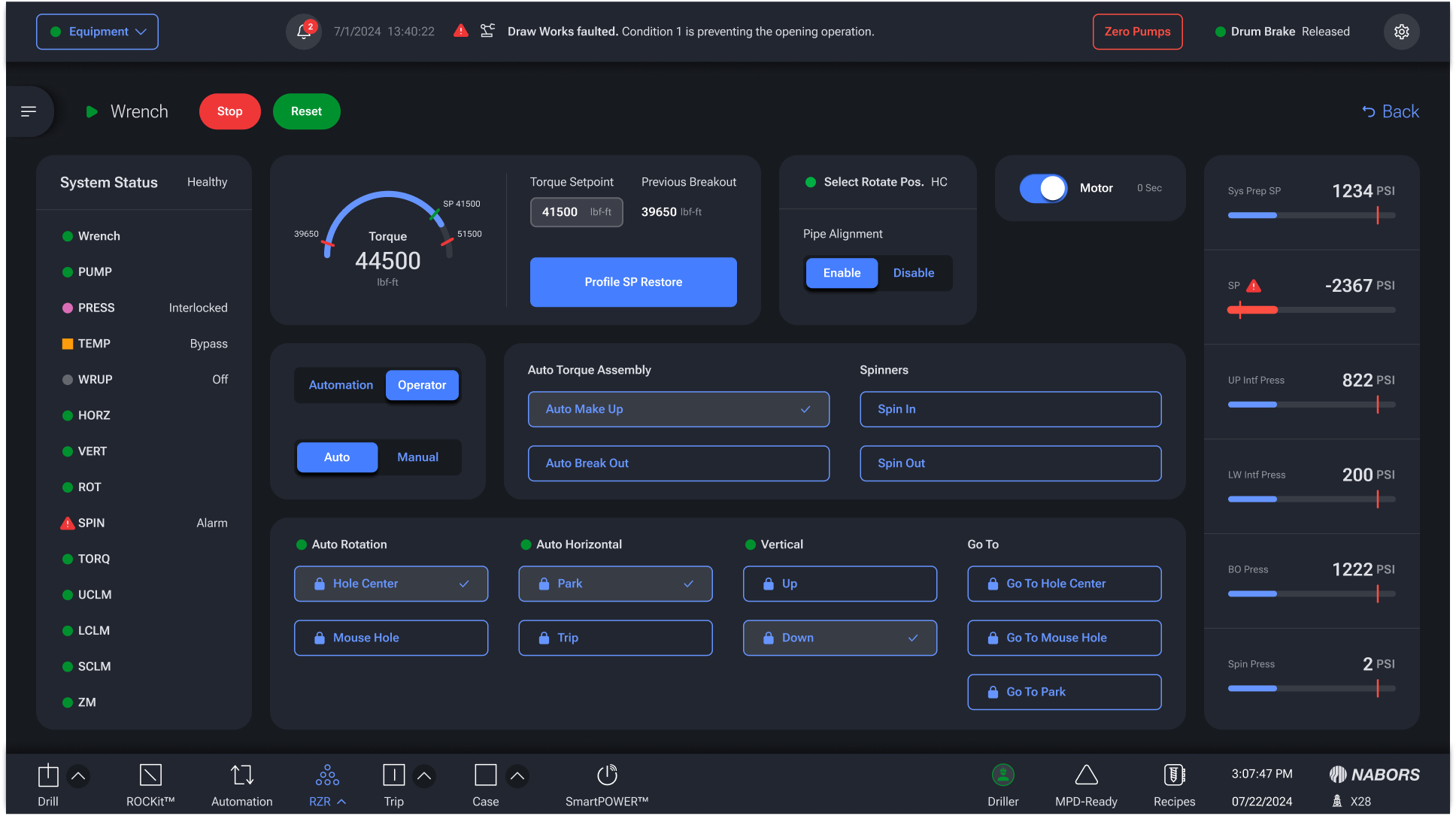

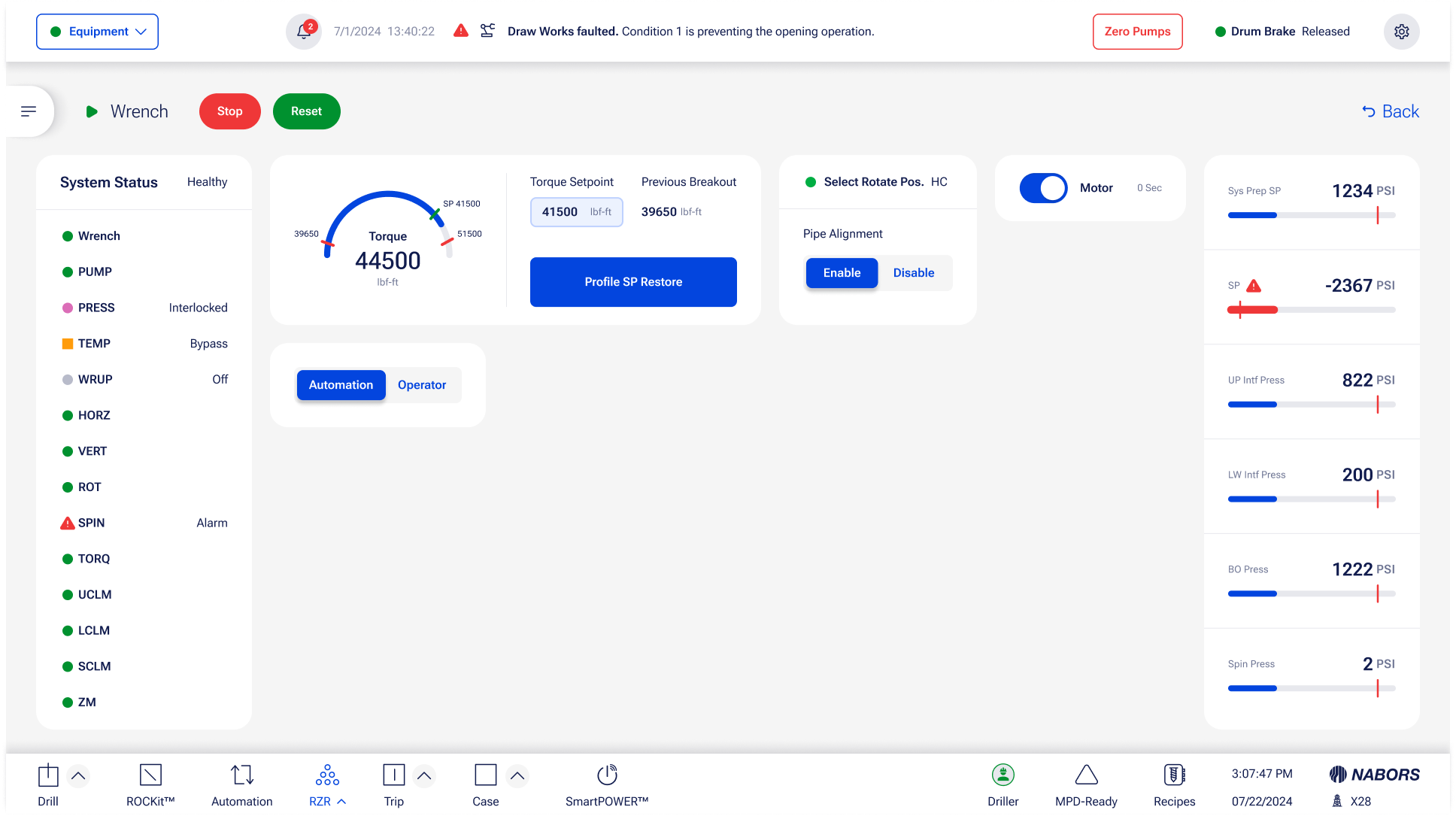

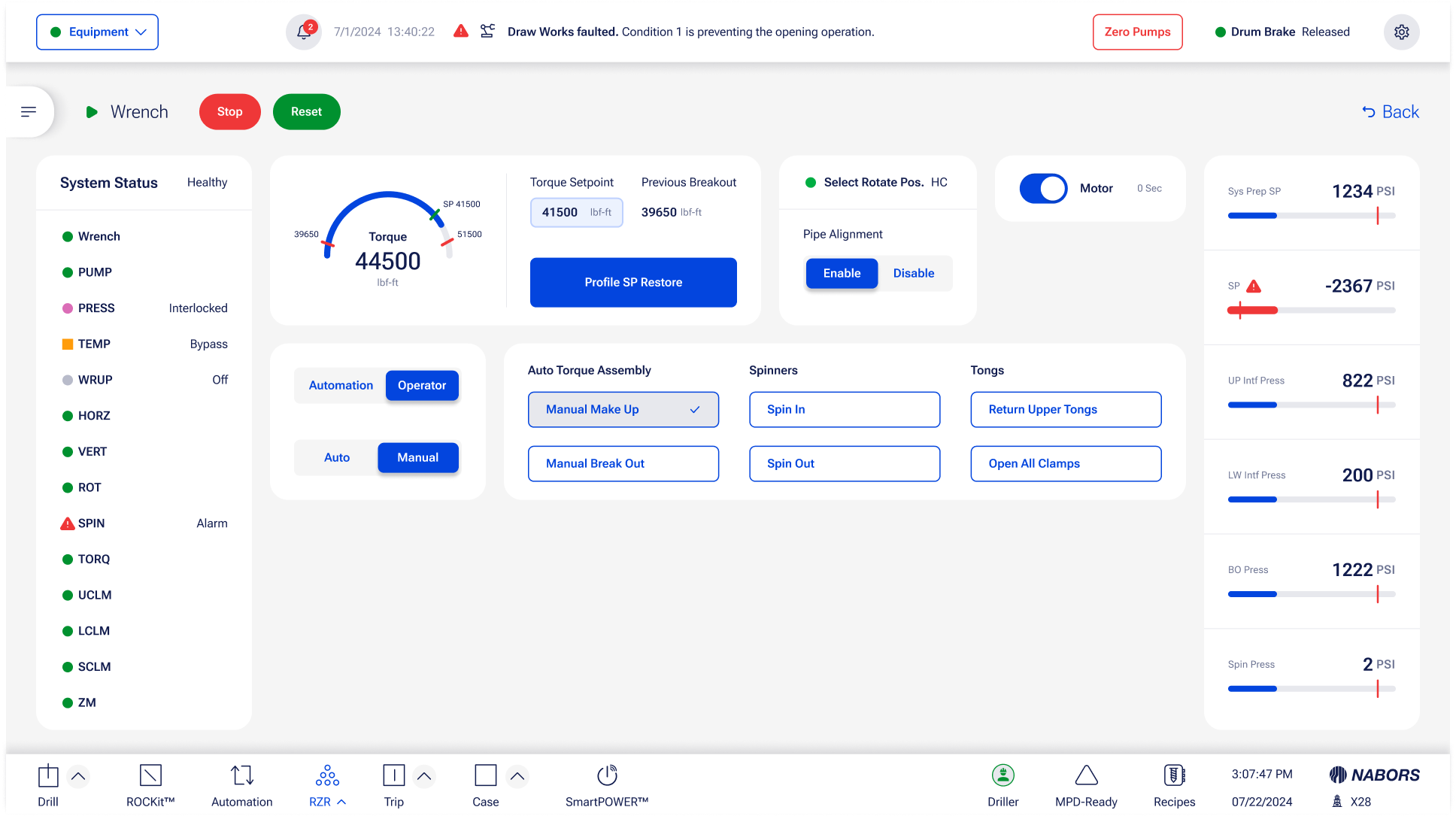

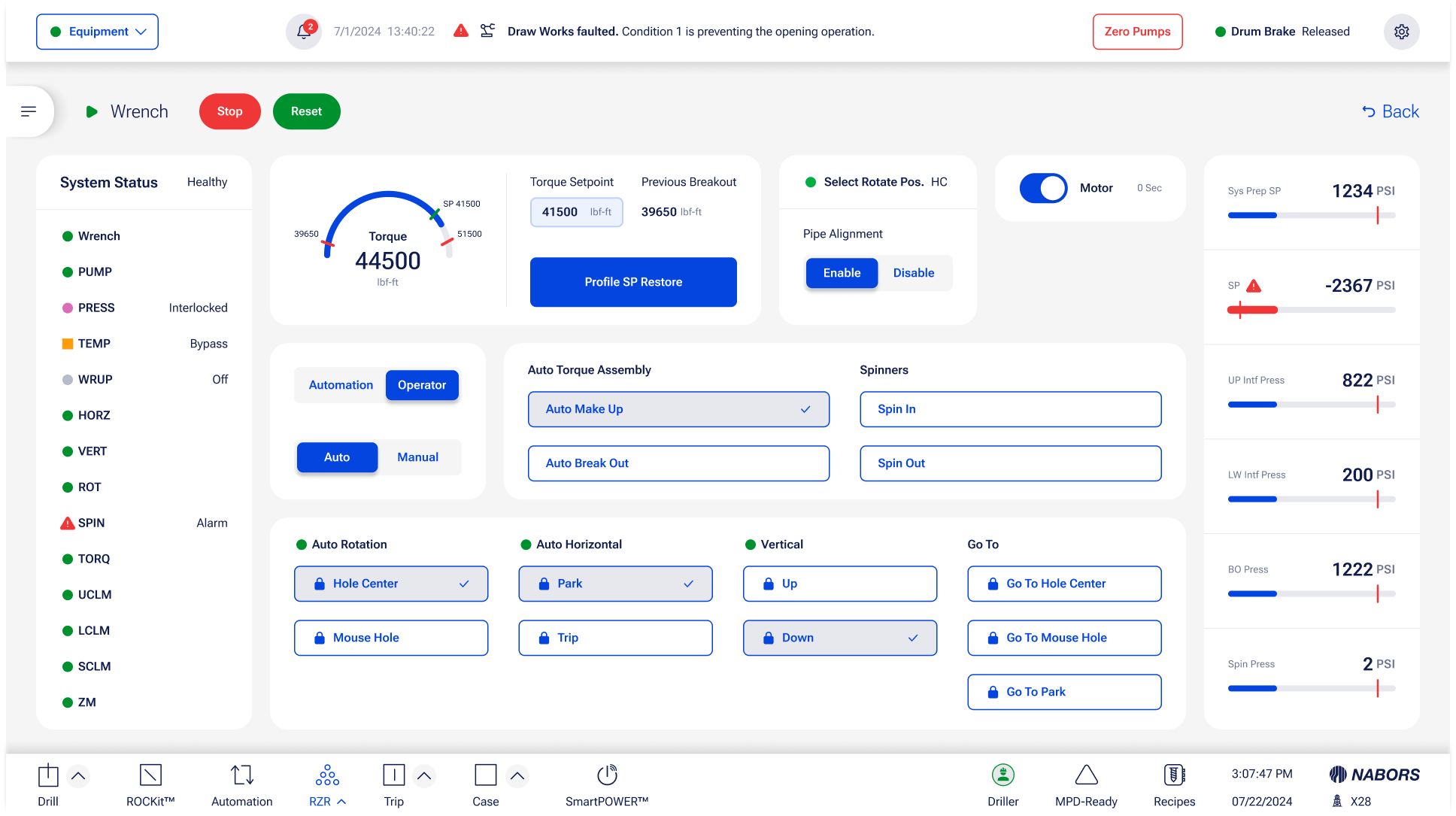

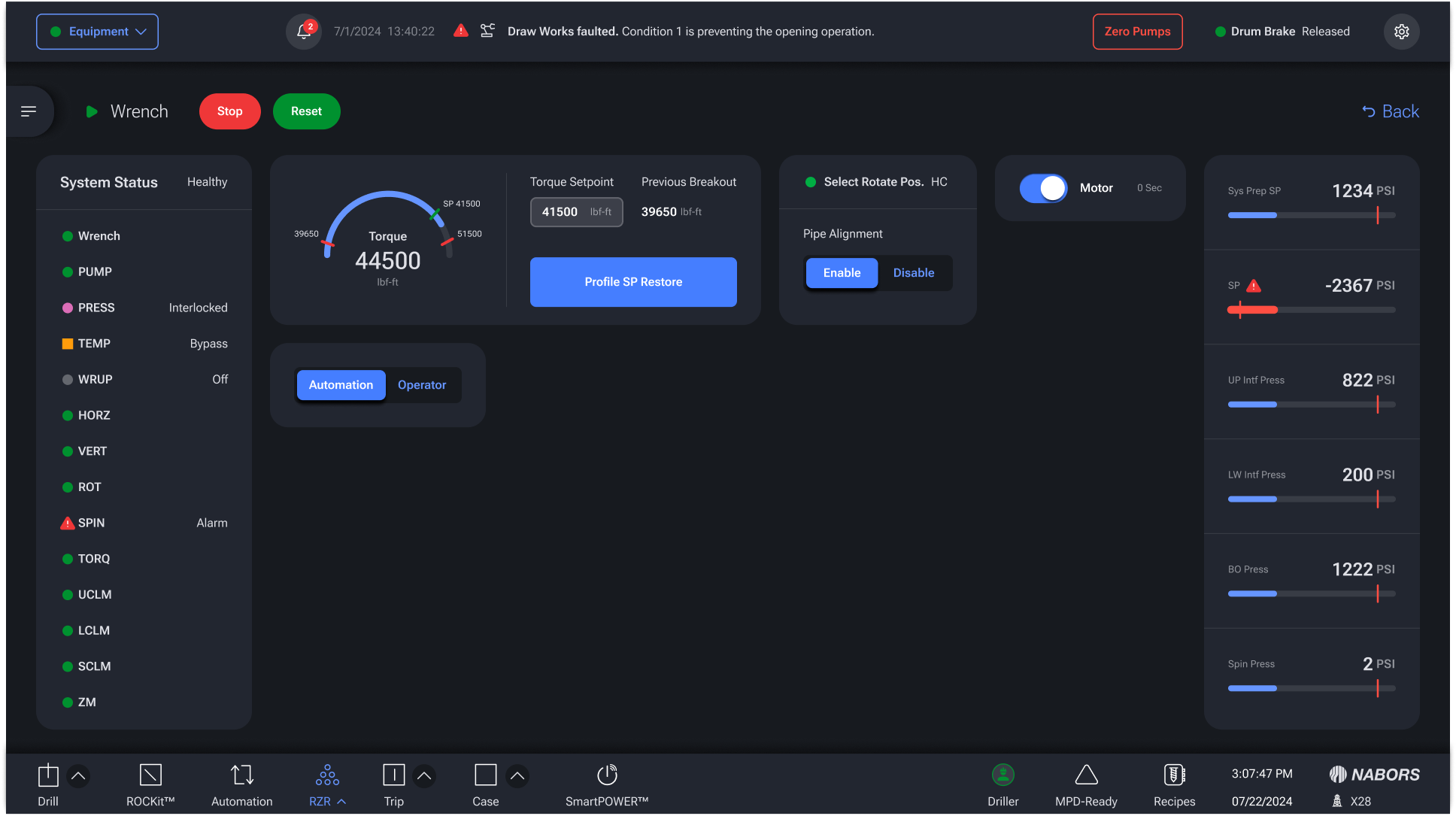

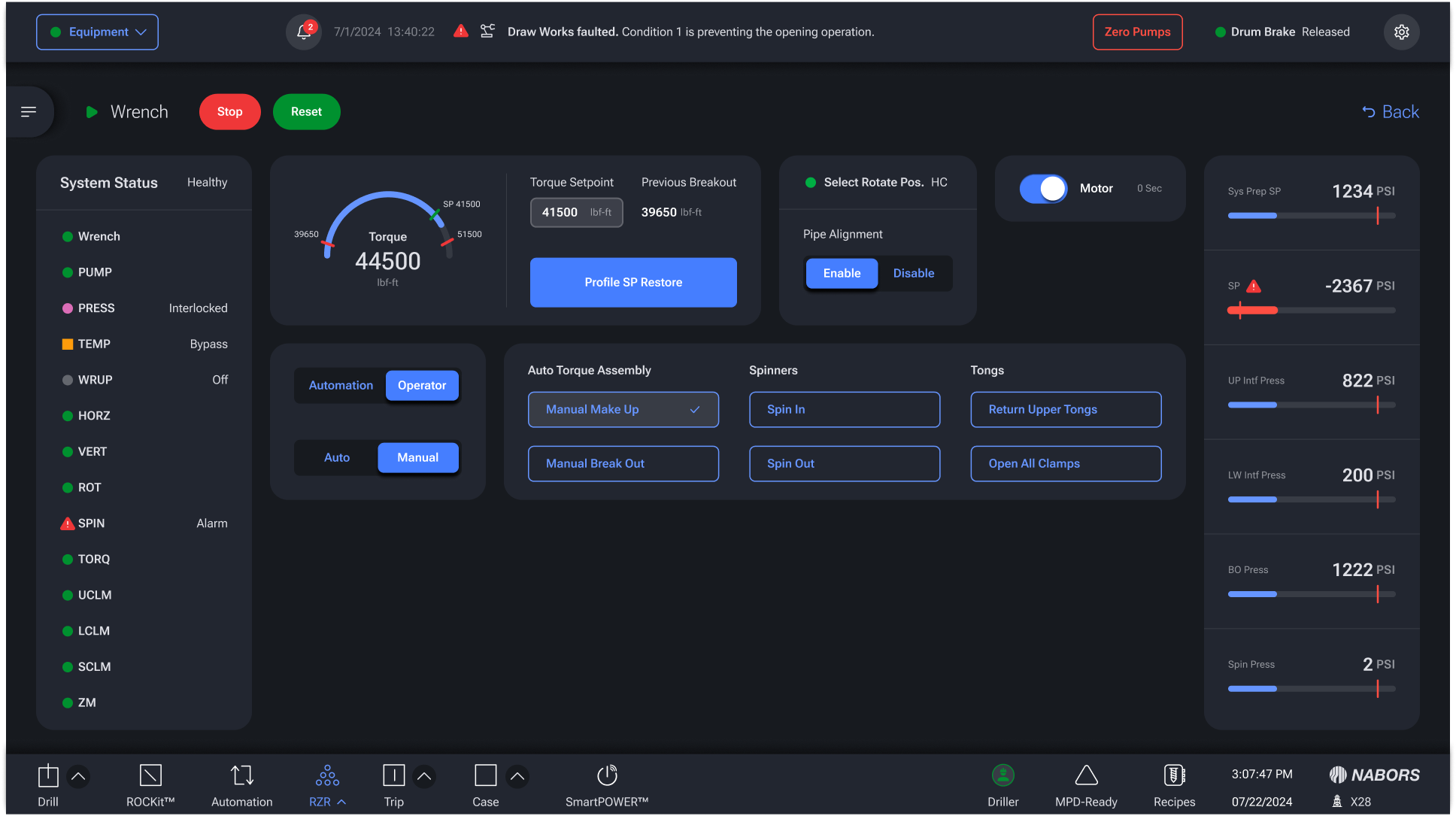

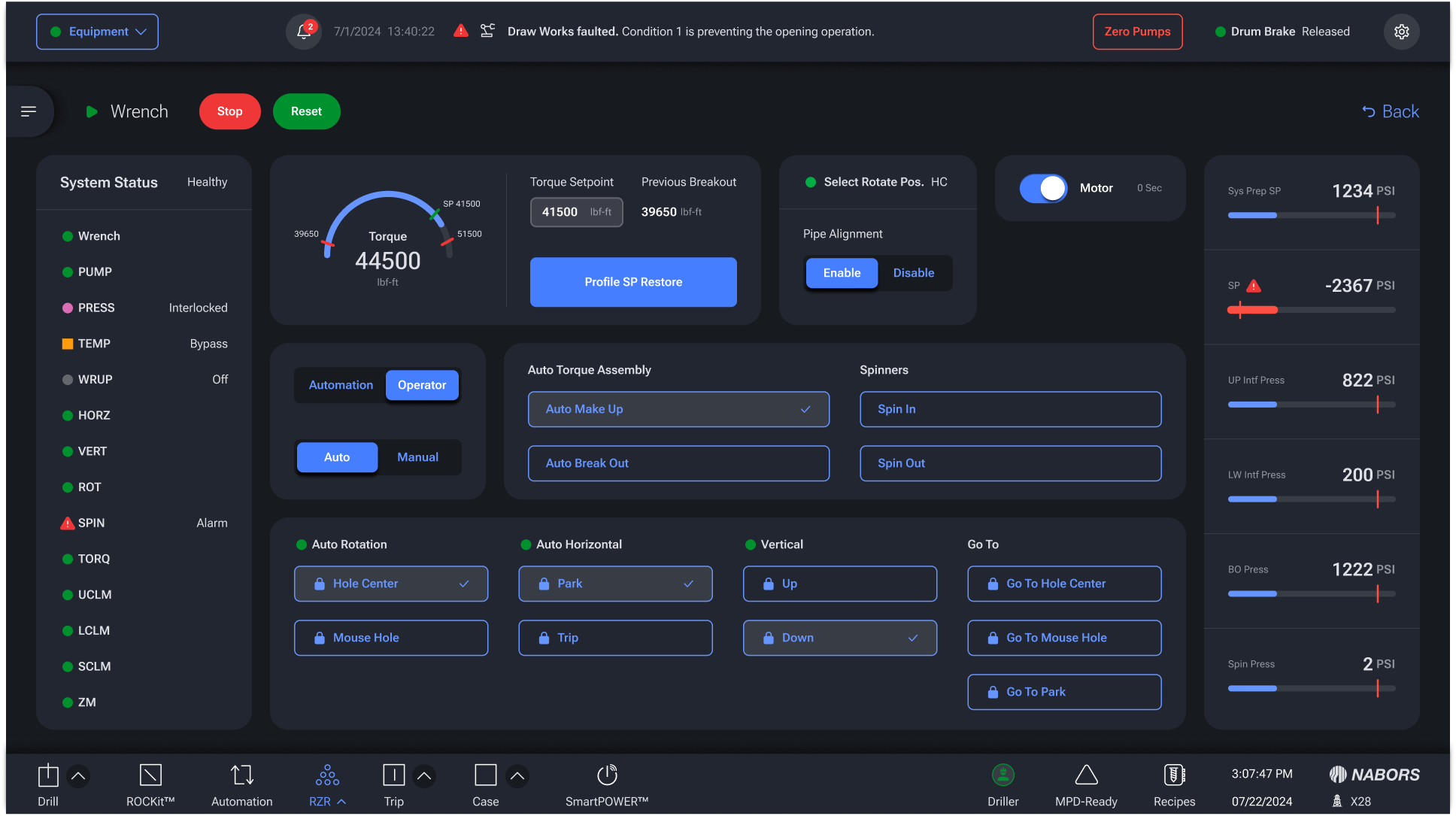

Wrench’s equipment screens had 3 different states depending on driller needs: Automation, Operator/Manual, Operator/Auto. Each state showed different inputs and controls as some were concerned with monitoring only and others involved some action to be carried out by the driller.

Wrench (Light + Dark Mode)

Previous Wrench

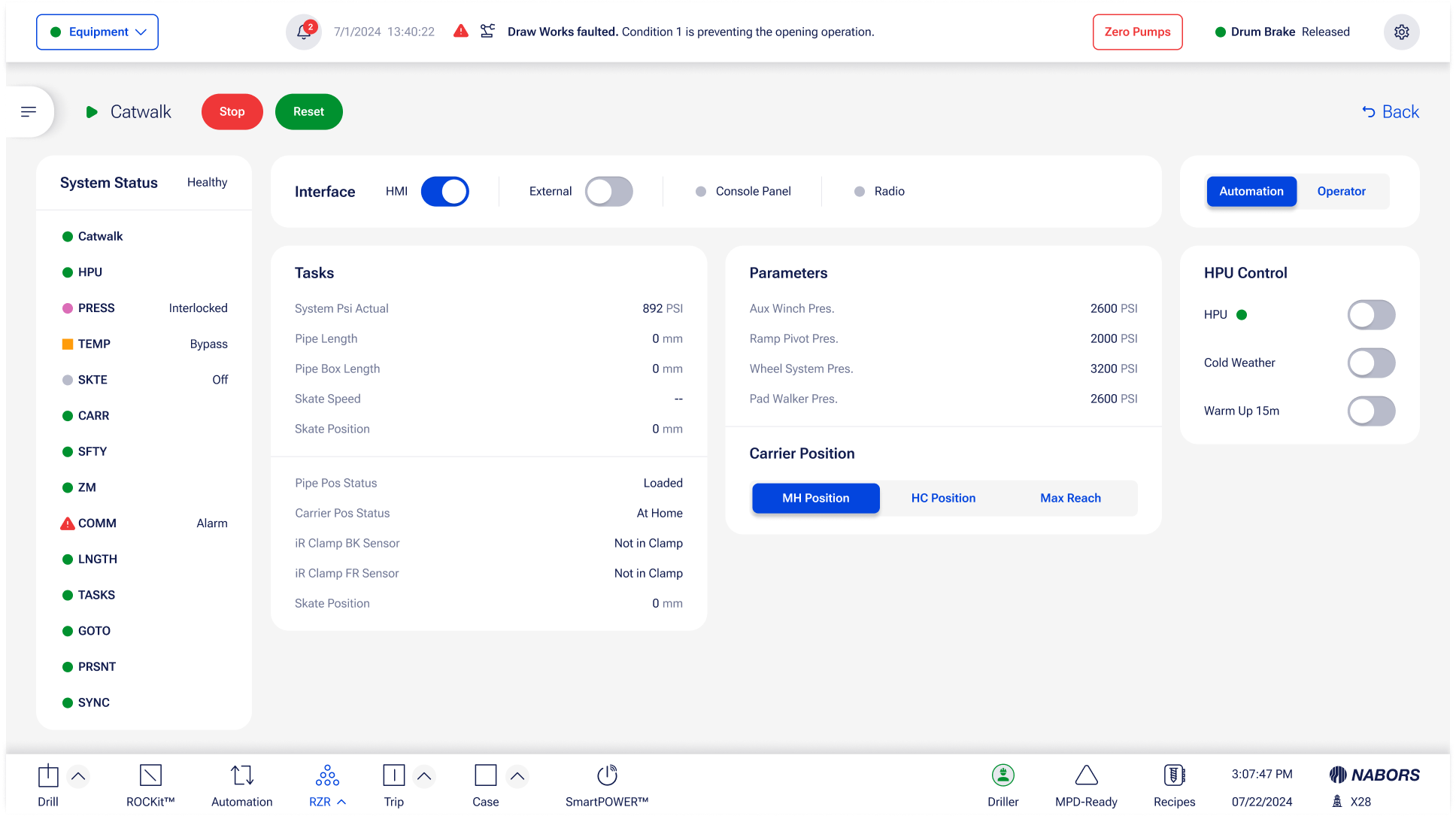

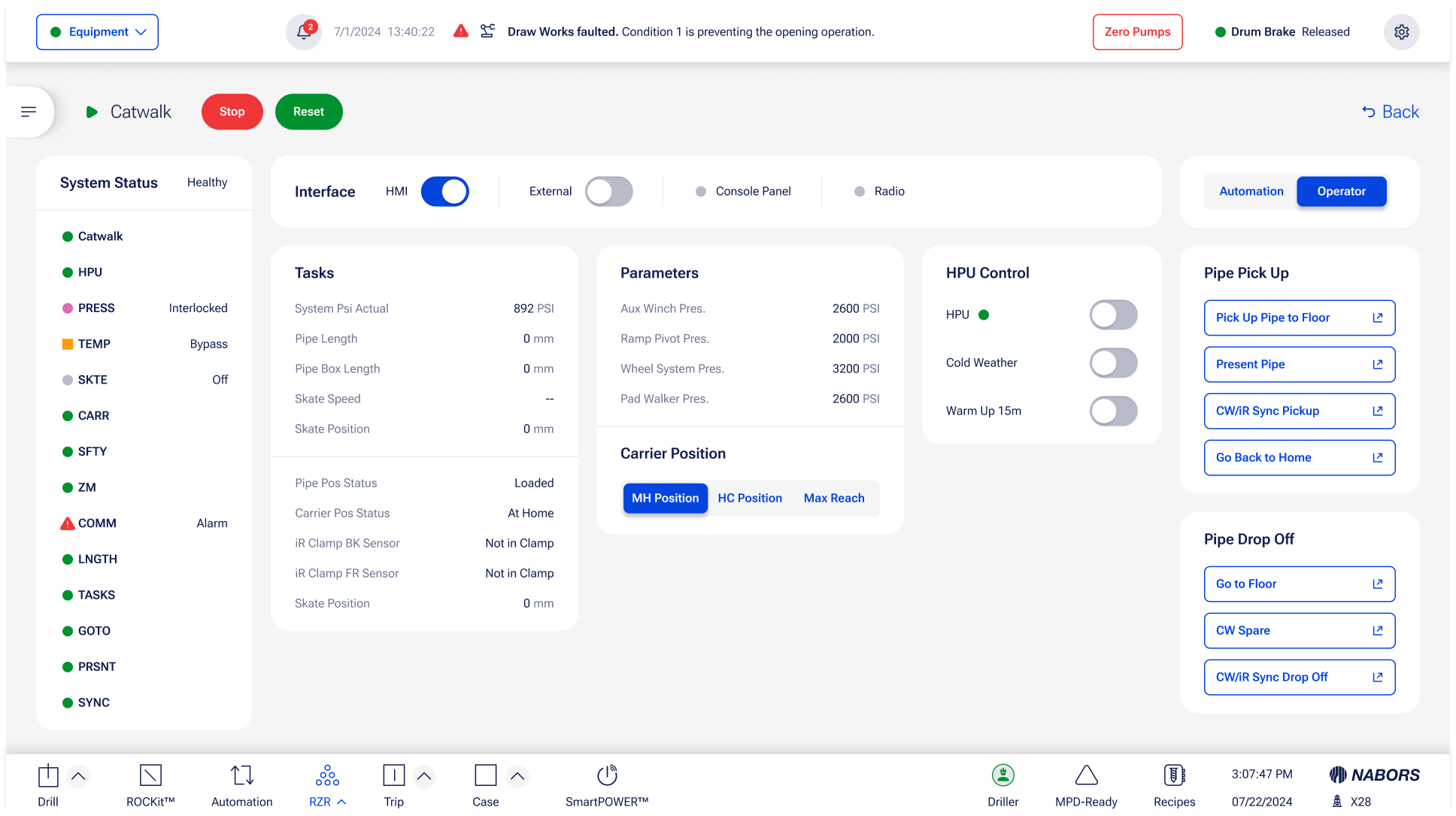

Catwalk enables pipes to be brought from the ground onto the rig to then be placed in the fingerboard. Catwalk’s screens remained primarily the same regardless of the states they were in, the only difference was the operator mode required controls for pipe pickup and pipe drop off.

Catwalk (Light + Dark Mode)

Previous Wrench

We tested the usability of the proposed RZR design by presenting representative Drillers with scenarios and asking them to complete tasks with a clickable prototype. Participants’ behavior was observed and their feedback was collected. Below is the insights about Driller behavior and recommendations to improve RZR design.

USABILITY TESTING

Participants

We tested the proposed RZR experience with a total of six participants who had overall drilling experience ranging from 1 to 7+ years and specifically with RZR ranging from 6 months to 2 years.

Workflow Efficiency: Determine whether drillers can accomplish their tasks as well or better than with their current interface.

Design Efficacy: Determine whether the navigation, layout, flow, interactions, and feedback support drillers’ goals in going through their daily workflows in RZR.

Findability: Determine whether equipment, workflow, and corresponding information are findable.

Transition from Existing System: Determine whether Drillers would welcome the new designs and find the design changes clear, learnable, and helpful.

Testing Goals

Six representative RZR Drillers participated in individual remotely-moderated 60-minute sessions where they were asked to accomplish simulated tasks with a clickable Figma prototype. The prototype was displayed on 2 different HMI monitors running simultaneously in order to recreate the experience Drillers would encounter in the doghouse. Note that the prototype had limited functionality, so users were not able to fully interact with every feature.

Participants were first given 10 minutes to explore the prototype and given a guided tour by a RZR trainer to simulate training. Then they used the prototype to assess key elements of the proposed RZR HMI design within the context of scenarios typically encountered on the rig.

Methodology

The following scenarios were presented to the participants:

Scenario 1:

- Create, assign, and activate groups in Fingerboard

- Setup automation of building stands for drilling

- Monitor drilling and stand building during normal operations

Scenario 2:

- RZR Fault of iRacker & Catwalk handoff

Scenario 3:

- Setup for tripping out automation

Scenario 4:

- ZMS collision warning

Scenario 5:

- RZR fault of failed to grab pipe from Fingerboard and ams won’t retract

Scenario 6:

- Virtually match pipes from Well Center to Fingerboard when iRacker goes down and need to manually trip out of hole

- Verify equipment is ready for automation when iRacker back up and running

Scenarios

Prototype

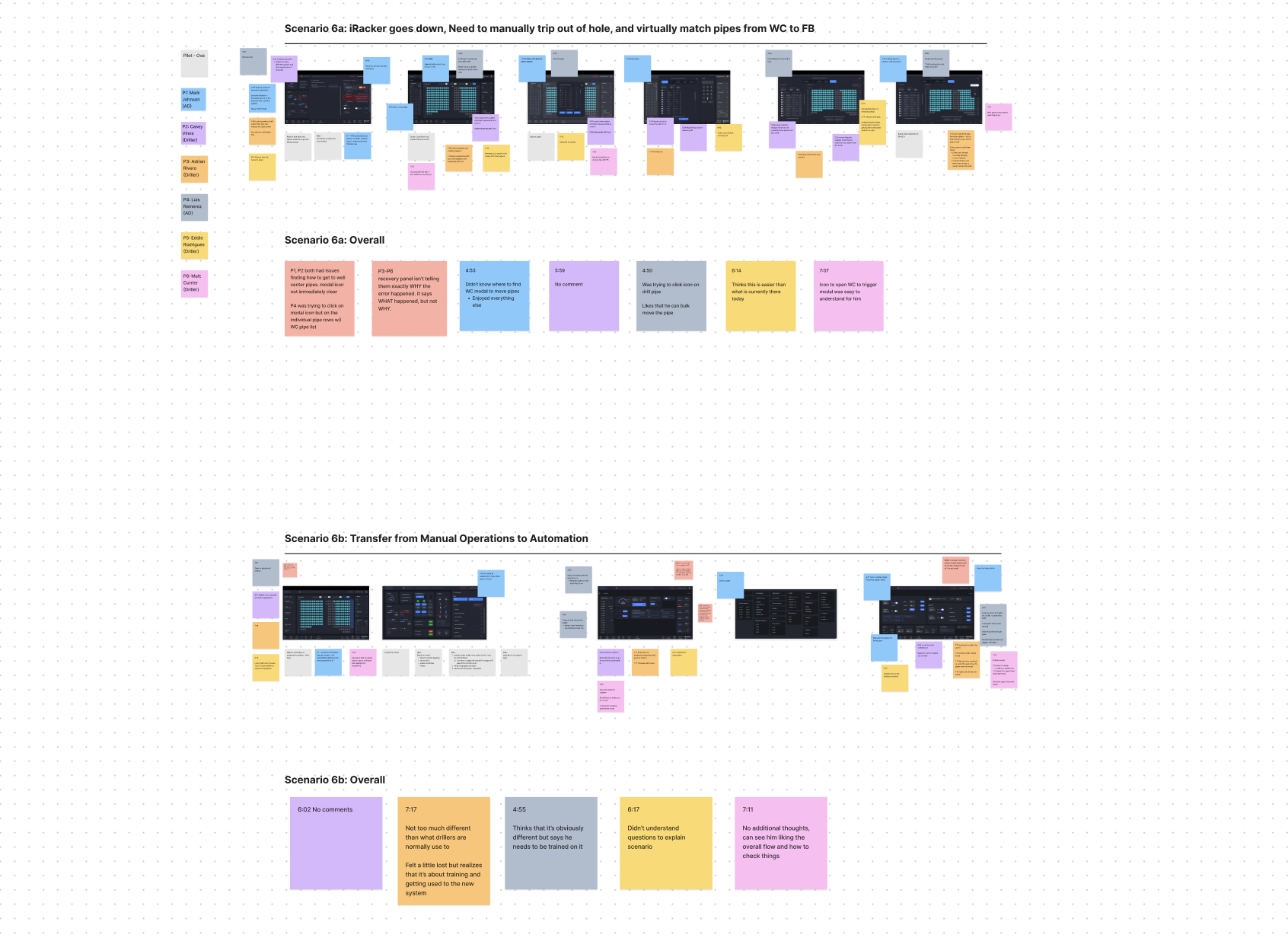

To effectively capture and record notes during usability testing we set up a FigJam. This helped us map notes to specific areas in the experience that were being tested as well as allow for easy and effective collaboration.

Usability Testing Observations

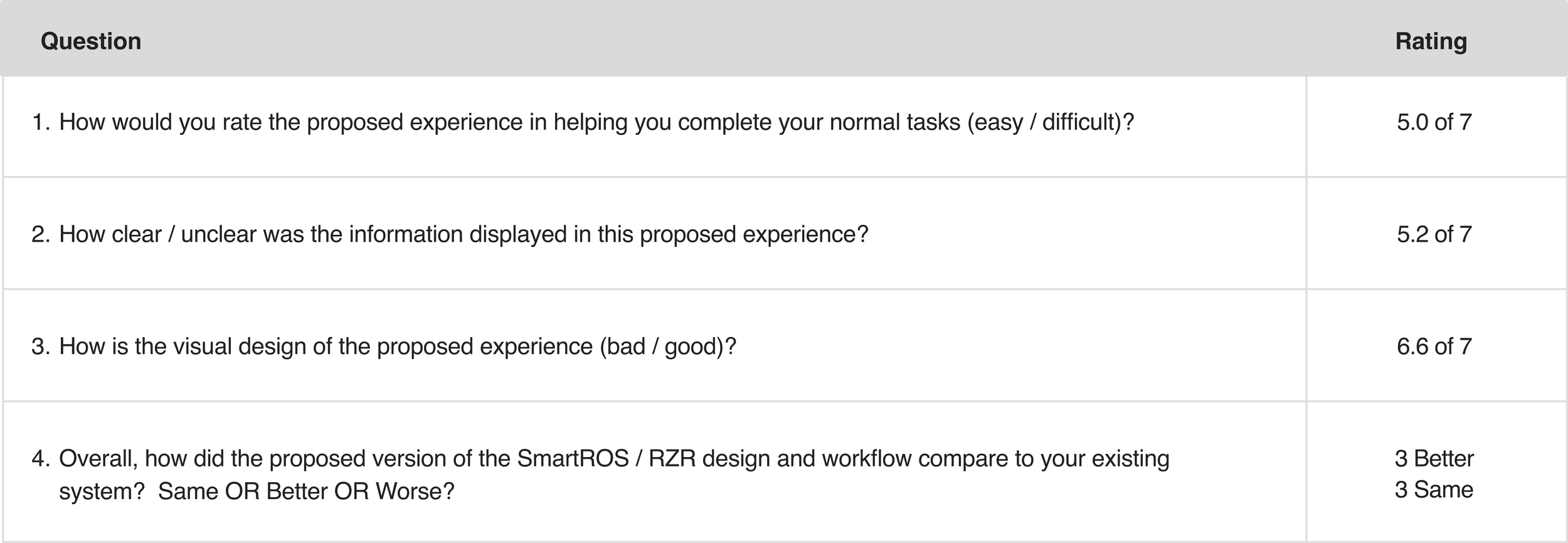

Overall Ratings

Six participants were asked to rate their experiences on a scale from 1 (negative) to 7 (positive) and overall how it compared to their existing system.

Key Insights and Recommendations

Based on our observations of drillers during the usability test and their feedback, we compiled a list of recommendations for improved RZR design.

Some of the recommendations were already redesigned and incorporated into the prototype based on patterns that emerged during the first day of testing. These design changes were then tested with Drillers on the second day to validate whether they improved usability.

Rename the “Edit Slots” Toggle

When asked to setup Fingerboard groups, Drillers did not understand that “Edit Slots” meant assigning slots to groups and selected “Edit Active Groups” instead, most likely because that control contained the word “groups” in it. They needed help to select “Edit Slots”.

Updated Post Usability Testing

Better distinguish between the two toggles based on function.

“Edit Slots” could be renamed to “Edit Groups / Slots”

“Edit Active Group” could be renamed to “Active Group”

Make Group Assignment Clearer

Drillers were not clear that a group had been assigned to slots because the group designations (G1, G2, etc.) were too small and not prominent enough.

Updated Post Usability Testing

Consider adding a micro-interaction to show rows have been successfully assigned.

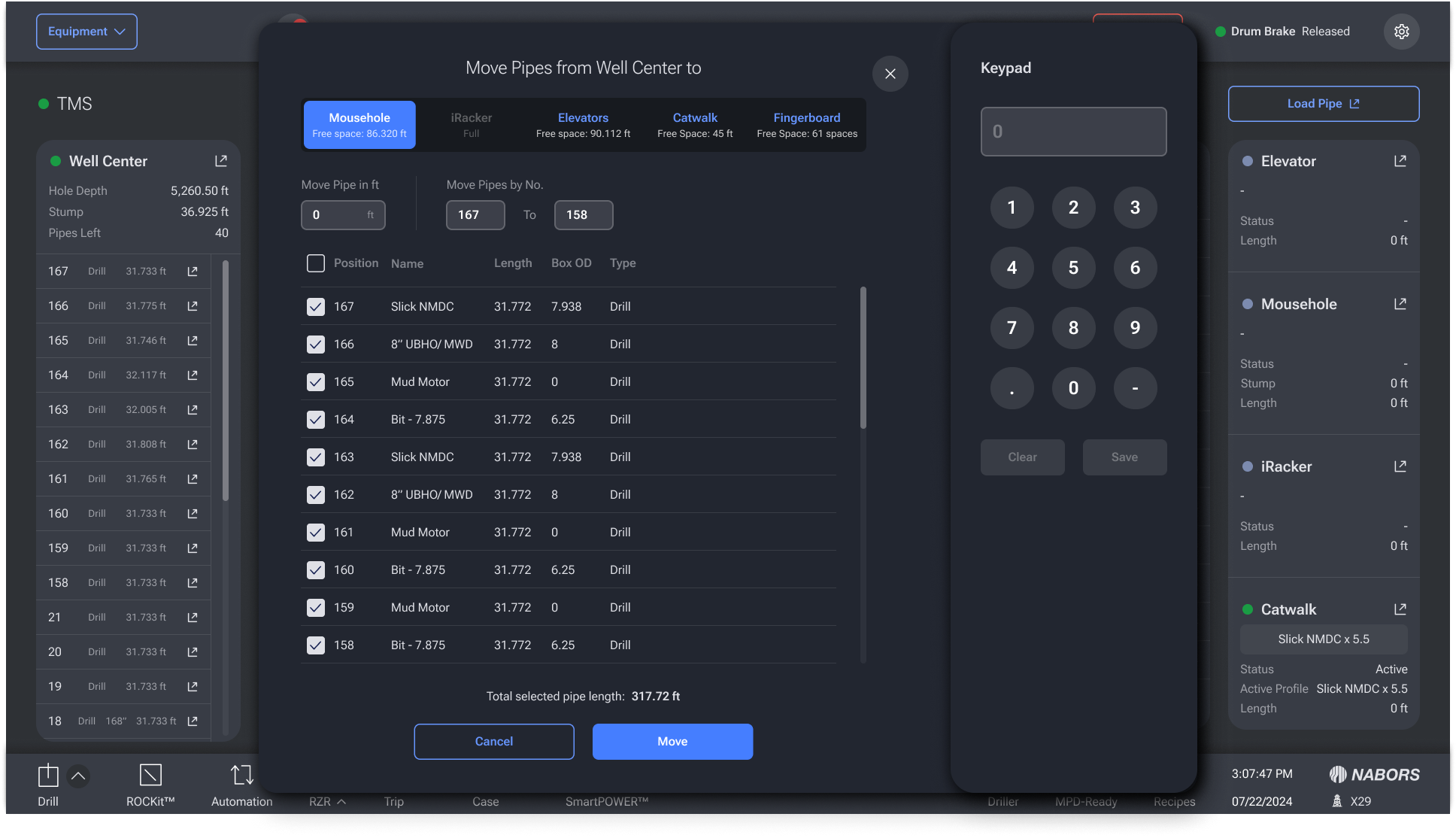

Make it Clearer How to Move Pipes from Well Center

When asked to move pipes out of the Well Center into the Fingerboard, Drillers had a hard time locating which control would allow them to select and move the pipes. They were tempted by the “Move Pipe from FB” toggle most likely because it had the word “move” in it. They required help to find the icon to the right of Well Center.

Updated Post Usability Testing

Make the Move Button more obvious and prominent. This could require changes to other parts of the Move flow.

Add More Helpful Information to the Automation Panel

Drillers noted that the automation panel was missing important information that would help them understand and fix the issue.

Updated Post Usability Testing

Show the number of pipes left within the automation panel. Even though this info is in the WC panel of the screen, including it in the automation panel would be helpful because that’s where Drillers will be looking the most.

Add helpful contextual information such as the racker weight before it faulted.

Drillers mentioned wanting to see the diameter of the pipe, although this might no longer be needed with the RZR approach of being more automated?

Make Equipment Screen Control Hierarchy & Layout Consistent

Drillers noted that the automation panel was missing important information that would help them understand and fix the issue.

Updated Post Usability Testing

Show the number of pipes left within the automation panel. Even though this info is in the WC panel of the screen, including it in the automation panel would be helpful because that’s where Drillers will be looking the most.

Add helpful contextual information such as the racker weight before it faulted.

Drillers mentioned wanting to see the diameter of the pipe, although this might no longer be needed with the RZR approach of being more automated?

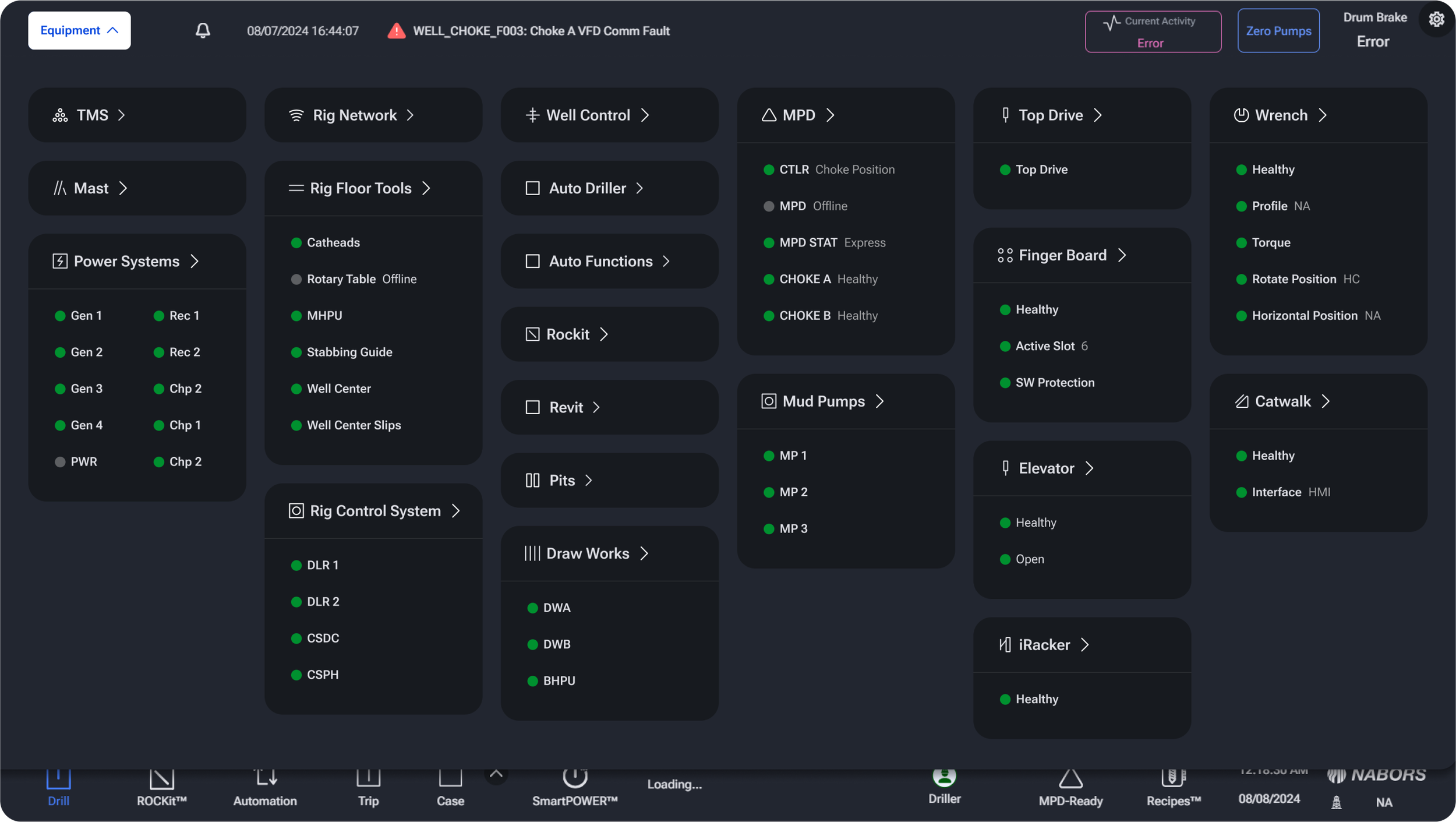

Categorize and Sort Equipment Dropdown Navigation Items

Participants had a hard time scanning through and finding the specific pieces of equipment within the Equipment Panel.

Updated Post Usability Testing

In the new equipment dropdown design, we focused on alphabetizing equipment for more efficient scannability.

Show stronger correlation with recovery options and the automation panel

Drillers didn’t always understand that recovery options were linked with the automation panel and a specific machine. Drillers were also distracted by the equipment panel on the left, especially since the faulted equipment was highlighted with red and the panels had less of a visual distinction between them.

Designed and used in prototype in second-half of testing

We modified the prototype design by incorporating a modal overlay between the recovery options drawer and the main screen components, allowing drillers to focus their attention on automation and recovery.

After adding the overlay, Drillers were able to see recovery options more clearly, significantly reducing confusion on the scenarios where recovery was tested.

A Driller noticed that the iRacker screen was missing the correct elevator controls.

Designed and used in prototype in second-half of testing

The prototype was updated to reflect the appropriate Elevator controls, providing a more accurate experience for the remaining participants.

Update Elevator Functionality for iRacker

RESULTS

In the span of 3 months we were able to update the Nabors RZR platform from the previous, outdated experience to a new, more modern and versatile experience with an emphasis on ensuring automation and workflow improvement.

In meetings with stakeholders and during usability testing, we saw our newly designed platform effectively address driller’s needs when completing their everyday tasks. In the platform’s previous experience, drillers relied heavily on having to look at 3 screens simultaneously; we solved for this by reducing the number of redundant on-screen elements and duplicative pages while also maximizing screen real estate, reducing the cognitive load for drillers and allowing them to only focus on 2 screens.